Unleashing the Power of Precision: CF8 Investment Casting for Superior Valve Bodies

Author: SAIVS Date Published: Jan 10,2024

Investment Casting, with a history spanning over 5,000 years, endures in modern manufacturing.

It entails crafting a wax replica of the desired part and coating it in refractory ceramic to create a mold.

Once the ceramic sets, the wax is melted, leaving a cavity. Molten metal is poured in, solidifies, and,

after breaking away the ceramic shell, yields a finely finished, accurately shaped part.

Ideal for intricate valve components, investment casting excels in achieving complex geometries and high dimensional accuracy.

The investment casting process for valve bodies:

Pattern making: A master pattern of the valve body is created, typically using wood, plastic, or metal.

Wax pattern replication: The master pattern is used to create multiple wax replicas of the valve body.

Investment mold making: The wax patterns are dipped in a slurry of refractory material, which hardens around the wax to form a mold.

Wax burnout: The wax is melted out of the mold, leaving behind a cavity in the shape of the valve body.

Metal pouring: Molten CF8 stainless steel is poured into the mold, filling the cavity left by the wax.

Cooling and solidification: The mold is allowed to cool and solidify, forming the final valve body.

Finishing: The valve body is then cleaned, inspected, and machined to its final dimensions and specifications.

Advantages of CF8 investment casting for valve bodies:

High dimensional accuracy: The investment casting process can produce valve bodies with very precise and intricate features.

Excellent surface finish: The castings have a smooth and consistent surface finish,

which can be important for applications where hygiene or aesthetics are important.

Strength and integrity: The investment casting process produces strong and durable valve bodies that can withstand high pressures and temperatures.

Design flexibility: The process is suitable for casting complex shapes and geometries, making it ideal for designing custom valve bodies.

CF8 stainless steel, a champion of austenitic alloys, reigns supreme in the realm of valve body investment casting.

It's secret? It is a cunning blend of chromium and nickel, granting it the perfect balance of corrosion-busting resistance and unwavering strength.

This steel, a master of malleability, dances effortlessly under the welder's touch and shapes itself to even the most intricate designs.

And let's not forget its fiery spirit, retaining its fortitude even when the temperature rises.

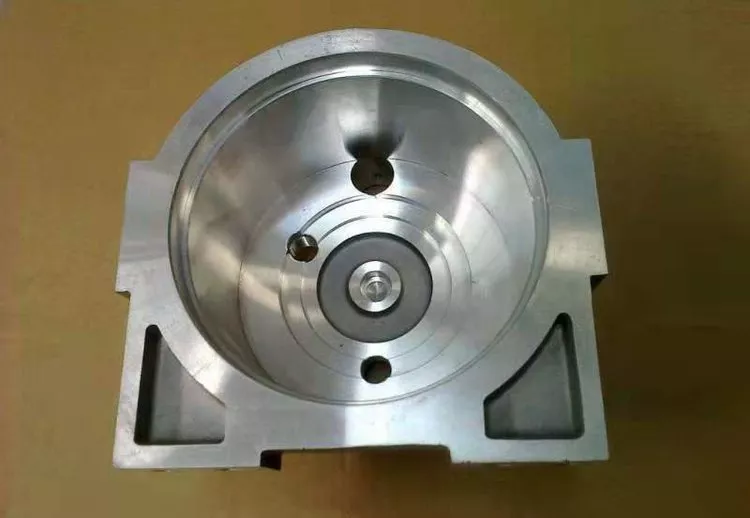

CF8 Stainless Steel Valve Body

Chromium's Corrosive Kryptonite:

The high chromium content in CF8 acts like a superhero shield, deflecting the attacks of corrosive fluids and aggressive environments.

This makes it the ideal choice for valve bodies facing the wrath of harsh chemicals, salty waters, or the unrelenting pressure of industrial applications.

Nickel's Toughening Touch:

Nickel, the loyal sidekick to chromium, enhances CF8's overall toughness and ductility.

Imagine it as a microscopic web, woven throughout the steel, adding an extra layer of resilience against cracks and fractures.

This dynamic duo ensures that valve bodies made of CF8 can withstand the harshest conditions,

emerging unscathed from the battlefield of industrial processes.

But why choose investment casting for these valiant valve bodies?

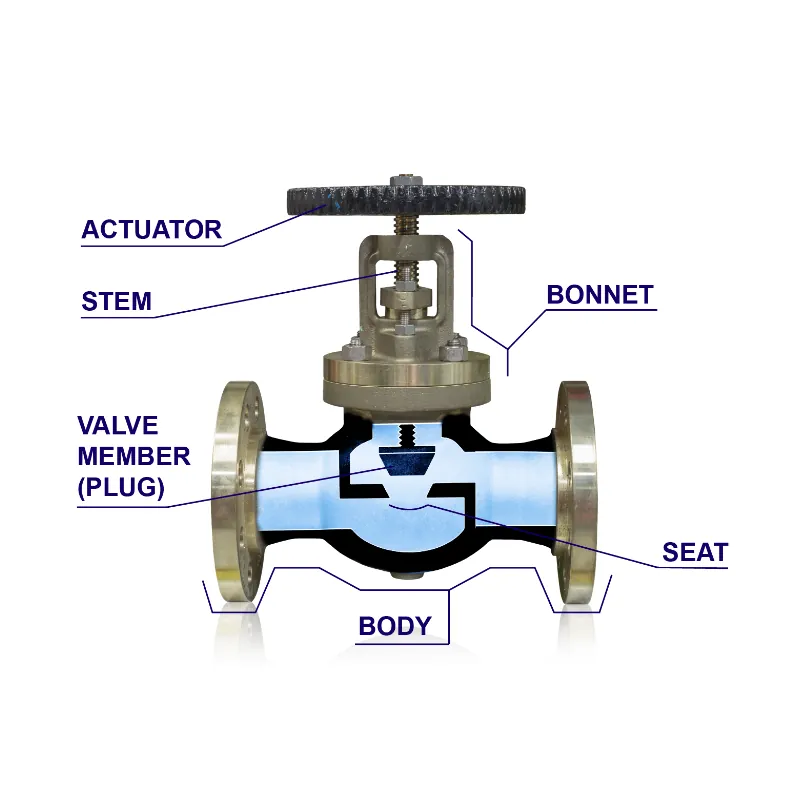

Precision and Complexity: Valve bodies are often intricate mazes of internal passages and delicate curves.

Investment casting, with its uncanny precision, replicates these features flawlessly,

maintaining tight tolerances and ensuring flawless dimensional accuracy.

Investment casting process

Material Versatility: This adaptable process welcomes a diverse range of materials, including the ever-reliable CF8 stainless steel.

Its corrosion resistance and mechanical properties make it a shining star in the valve body world.

Surface Finish Fit for a King: Investment casting delivers parts with a surface finish so smooth it would make a mirror blush.

This reduces the need for tedious secondary machining and finishing, saving time and resources.

Cost-Effectiveness: For Heroes of High Volume: When the production line hums with medium to high volumes,

investment casting reveals its true cost-saving potential. By minimizing material waste and reducing labor costs,

it becomes a budget-friendly champion for valve body production.

These factors invest in casting the perfect partner for crafting high-quality, durable valve bodies that meet and exceed industry standards.

But CF8's reign doesn't stop at the valve body. This versatile hero can be found in other crucial valve components as well:

Valve Disc

This flow-controlling warrior benefits from the precision of investment casting.

Aerodynamic profiles and intricate shapes become a reality, ensuring efficient and smooth fluid control.

Valve Bonnet

The leak-proof guardian of the valve body, the bonnet, finds its perfect match in investment casting.

Complex internal threading and a secure fit are its hallmarks.

Valve Bonnet

Valve Pump Components: From impellers to housings, the intricate parts of valve pumps thrive under the care of investment casting.

Dimensional accuracy and a flawless surface finish become their guiding principles.

Valve Pump Components

Just like the valve body, these components can be forged from the noble CF8 stainless steel,

ensuring their durability and resistance to even the most hostile environments.

Valve Casting Services in SAIVS Foundry

saivs Foundry is a top investment casting company, specializing in high-quality valve components.

From design to production, we offer comprehensive services, ensuring precision through advanced technology and strict Quality Control.

Proficient in materials like CF8 stainless steel, we meet diverse industry needs.

With a commitment to quality and extensive experience, we are the preferred choice for valve casting.

For inquiries, please email us for a free quote within 24 hours!

*Cited:https://www.investmentcastchina.com/cf8-investment-casting-of-valve-body/

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Porosity Issues in Aluminum Die Castings: Formation, Types, Effects, and Solutions

This article aims to provide a comprehensive overview of porosity issues in aluminum die castings.

-

How Vacuum Prevents Oxidation in Steel Heating

Introduction:Vacuum furnaces are specialized equipment used in heating processes that take place under low-pressure environments. The unique feature of a v

-

Top 3 Common Die Casting Mold Failures and Their Causes

The Common Failure Types and Causes of Die Casting ToolingDuring the operation of die casting molds, various types of damage and failure can occur, which s

-

How to Prevent Shrinkage in Die Castings

At present, the application of impregnation technology in the products of die-casting aluminum manufacturers is constantly expanding. China advocates for full i...

-

Aluminium Casting Vs. Steel Casting: Which Alloy Is Right For Your Product

Introducing Green Sand CastingCasting products are used in a variety of industries, making casting an important manufacturing process. Many of these products ar...

-

Why Choose Haworth Castings For Your Cast SAIVS?

SAIVS Castings specializes in producing high-quality cast enclosures for various industrial sectors. Enclosures are protective housings that provide a secure ba...