Porosity Issues in Aluminum Die Castings: Formation, Types, Effects, and Solutions

Author: SAIVS Date Published: Mar 29,2024

Introduction

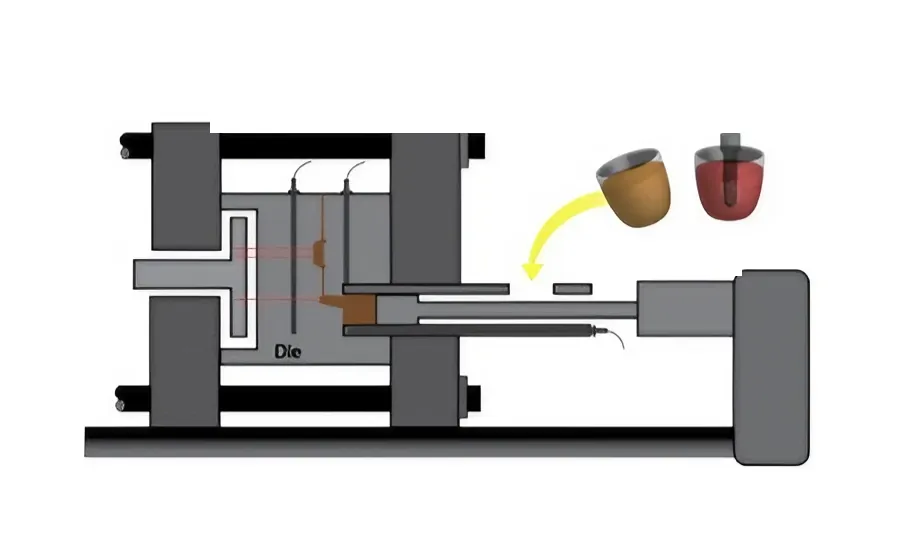

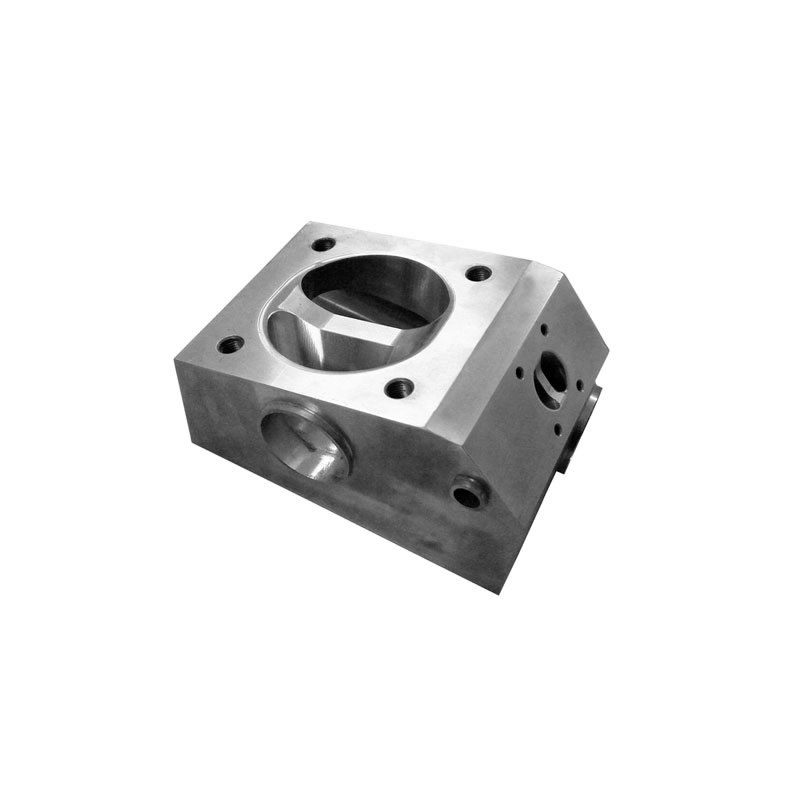

Die Casting is a widely used manufacturing process for producing complex metal parts with high efficiency, particularly in the aluminum die casting process.

However, the occurrence of porosity, which refers to the presence of small voids or gas pockets within the casting,

can significantly deteriorate the quality and performance of the final product.

This article aims to provide a comprehensive overview of porosity issues in aluminum die castings, including its formation mechanisms, types, impact, and

potential solutions.

Formation Mechanisms of Porosity in Die Castings

Porosity in aluminum die casting defects can arise from various formation mechanisms, each contributing to the presence of voids or gas pockets within the

casting. Understanding these mechanisms is crucial for identifying and mitigating porosity issues in the manufacturing process.

Gas Entrapment: During the die casting process, various sources can introduce gases into the molten metal,

such as entrapped air, moisture from the mold, and gas byproducts from the reaction between molten metal and mold coating.

If these gases are not effectively removed, they can be trapped in the solidifying metal, leading to the formation of porosity.

Insufficient Metal Filling: When the molten metal fails to completely fill the mold cavity due to inadequate gating system design,

improper injection parameters, or insufficient melt volume, it can result in unfilled areas or "shrinkage cavities" within the casting.

Poor Metal Flow: Factors such as improper Mold design, incorrect sprue and runner design,

and high viscosity of the molten metal can impede its smooth flow during filling,

resulting in the formation of trapped air pockets and incomplete filling, which can lead to porosity.

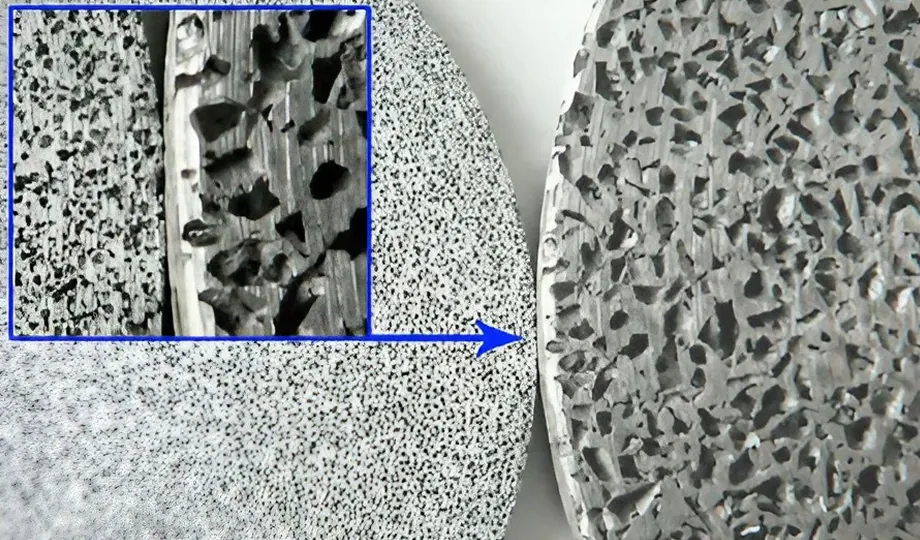

Types of Porosity in Die Castings

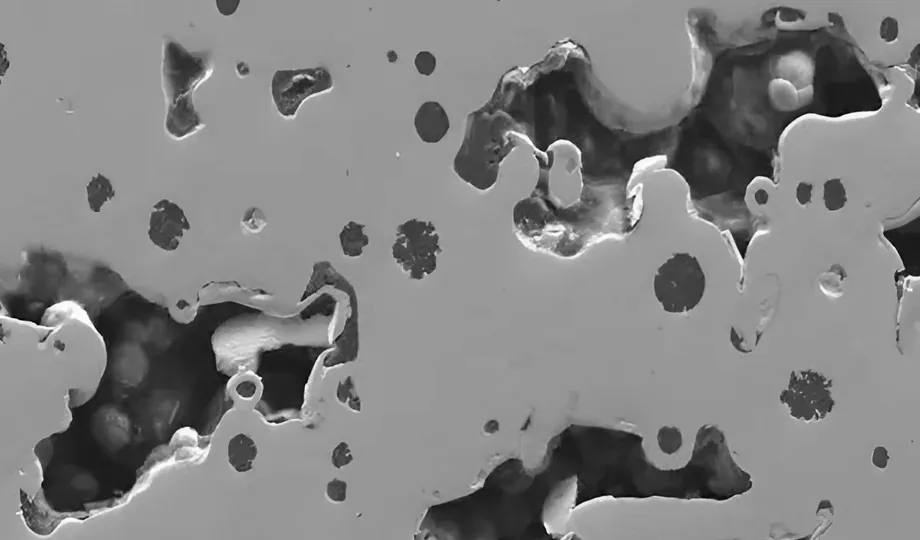

Gas Porosity: This is the most common type of porosity, characterized by spherical or irregular-shaped voids caused by entrapped gases.

Shrinkage Porosity: This type of porosity occurs when the molten metal contracts during solidification, resulting in the formation of shrinkage cavities.

Other Types: Other forms of porosity may include pinholes, microporosity, and interdendritic porosity, which can be attributed to various factors such as mold

contamination, alloy composition, and solidification conditions.

Impact of Porosity on Die Casting Performance

Strength and Mechanical Properties

Porosity can significantly reduce the tensile strength, fatigue strength, and impact toughness of die castings,

leading to increased susceptibility to cracking and failure under mechanical loading.

Thermal and Electrical Conductivity

The presence of pores can impede the heat transfer and electrical conductivity of the casting,

affecting its performance in applications that require efficient heat dissipation or electrical conduction.

Surface Quality

Porosity can create a rough and uneven surface finish on the casting,

which may be unacceptable for aesthetic reasons or functional requirements such as sealing or mating with other components.

Technical Approaches to Solve Porosity Issues in Die Castings

Process Optimization

This involves adjusting various process parameters such as injection pressure, injection speed, melt temperature,

venting, and holding pressure to minimize gas entrapment, improve metal filling, and enhance the overall casting quality.

Material Selection

Selecting die casting alloys with lower gas content, better fluidity, and optimized solidification characteristics

can help reduce the formation of porosity and improve the overall quality of the castings.

Design Optimization

Incorporating design features such as proper gating system design, optimized runner and sprue dimensions,

and strategic use of risers can facilitate smooth metal flow, minimize air entrapment, and promote uniform solidification, thereby reducing porosity.

Vacuum Impregnation Technology

This technique involves impregnating the casting with a low-viscosity sealant under vacuum conditions,

which effectively fills the pores and eliminates any air pockets, resulting in a dense and void-free casting.

Measurement and Management of Porosity

Porosity Measurement Methods

Various methods are employed to quantify the extent of porosity in die castings, including ultrasonic testing, radiography, and metallographic examination.

Acceptable Porosity Level

The allowable porosity level depends on the application and performance requirements of the casting.

Quality standards such as ASTM standards provide guidelines for acceptable porosity levels in different types of castings.

Conclusion

Porosity is a critical issue in die castings that can significantly impact the quality and performance of the final product.

By understanding the formation mechanisms, types, and impact of porosity, manufacturers can implement

effective technical solutions and Quality Control measures to minimize its occurrence.

This includes optimizing process parameters, selecting suitable materials,

incorporating design features that promote proper metal flow and solidification, and employing technologies such as vacuum impregnation.

Additionally, accurate measurement and management of porosity levels are crucial to ensure the quality and reliability of die castings in various applications.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Unlocking the Future of Manufacturing with Advanced Aluminum Alloy Die Casting Technologies

In the era of high-performance manufacturing, aluminum alloy die casting has emerged as a cornerstone technology that drives innovation across industries—f

-

Why Automotive Parts Use Zinc Die Castings

IntroductionIn the automotive industry, the use of high-quality materials is crucial for manufacturing durable and efficient components.Zinc die castings have g...

-

Why Investment Casting Is Cruial In The Railway Sector

The railway industry is one of the most important sectors in the world, with an extensive network of tracks and trains that transport goods and people across lo...

-

The Six Key Benefits of Lost Foam Casting

In the ever-evolving landscape of manufacturing, selecting the right casting method is crucial for efficiency and cost-effectiveness. Lost foam casting has

-

Brief analysis of the characteristics and advantages of aluminum die casting

Briefly analyze some characteristics and advantages of aluminum die casting.Aluminum die casting is a very popular manufacturing method in the process of produc...

-

Why Choose Haworth Castings For Your Cast SAIVS?

SAIVS Castings specializes in producing high-quality cast enclosures for various industrial sectors. Enclosures are protective housings that provide a secure ba...