Integrating CT and CAE Technologies in Die Casting for Smarter Quality Control

Author: SAIVS Date Published: Jul 21,2025

Digital Transformation of Die Casting: Intelligent Manufacturing and Real-Time Quality Control

Die casting has evolved into a highly digitalized and automated industry, particularly in sectors like automotive, aerospace, and consumer electronics. With increasing product complexity and quality standards, companies must embrace intelligent manufacturing processes. This article explores how digital technology such as CT inspection and CAE simulation is transforming the die casting industry.

Die Casting: A Digital-Ready Manufacturing Method

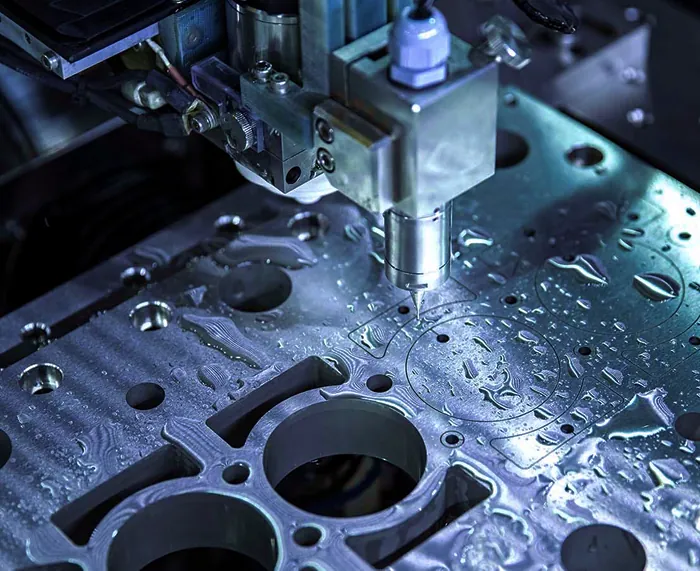

Die casting, or high-pressure casting, involves injecting molten metal into a mold at high speed and pressure. It’s widely used for producing lightweight, thin-walled components in both cold-chamber and hot-chamber processes. Cold-chamber die casting is ideal for larger parts like auto components, while hot-chamber is best suited for small electronics such as USB connectors.

Automation Foundation in Die Casting

Among all casting processes, die casting has the highest automation potential. Modern factories deploy automated die-casting islands, integrating dozens or hundreds of machines for seamless, continuous production.

These facilities utilize smart factory technologies to monitor real-time data from each machine. One typical use case is mold temperature control. By regulating the flow and temperature of cooling water, the system maintains thermal balance using feedback algorithms. This results in consistent product quality and minimal downtime.

Internal Defect Detection with CT Inspection

Traditional quality control methods like sampling or 2D X-ray fail to capture the full internal structure of a casting. With stricter quality requirements in the automotive sector, full 3D inspection has become essential.

Advantages of CT Technology

CT (Computed Tomography) allows for non-destructive 3D inspection of internal casting defects like porosity, voids, and inclusions. However, to integrate CT into real-time production, it must meet three conditions:

- High-speed scanning to match production throughput

- High-resolution images for defect recognition

- Fast software algorithms to process data efficiently

Speed-Scan CT systems, such as those used by Volkswagen, represent the forefront of this technology. However, their high cost remains a challenge for widespread adoption in domestic operations.

Process Feedback and Continuous Optimization

Once defect data is collected via CT, it can be analyzed to adjust process parameters. The goal is to use defect distribution insights to modify mold design, cooling strategy, or injection parameters.

Role of CAE Simulation

CAE (Computer-Aided Engineering) simulations enable virtual casting trials. By simulating metal flow, pressure, temperature gradients, and potential defect zones, manufacturers can fine-tune processes before physical production begins.

This data loop—CT inspection ➝ CAE simulation ➝ process adjustment—creates a feedback cycle that continuously improves casting quality and production efficiency.

Mastering Core Digital Technologies

Control over CAE technology is a benchmark of technical strength in die casting. Digital inspection converts physical data into digital form, and CAE analysis transforms this data into actionable engineering solutions.

If this CAE logic is eventually codified into automated algorithms, it becomes the basis of a fully autonomous intelligent casting factory. This represents the future of competitive manufacturing in the digital era.

Partner with Ningbo saivs Machinery for Digital Casting Solutions

At Ningbo Saivs Machinery Co., Ltd., we are committed to digital transformation in die casting. From automated production lines to CAE-powered process optimization, our expertise enables us to deliver precision-cast components at scale.

Whether you're an OEM or a tier supplier looking for advanced die casting solutions, our engineering team can support your smart manufacturing journey.

contact us today to discuss how digital die casting can enhance your production quality and efficiency.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Powder Coating: A Durable and Sustainable Finishing Solution

Powder coating offers a superior alternative to traditional liquid coatings. Learn about the process, composition, and FAQs about powder coating.

-

Characteristics of Sand Casting and Its Application

The production of aluminium alloy castings by sand turning casting with clay bonded sand as molding material has a long history and is also the most widely used...

-

5 CNC Machining Materials

AluminumAluminum is one of the most popular materials for CNC machining due to its excellent machinability, lightweight nature, and resistance to corrosion

-

CASTING OF THE YEAR: WAUPACA’S COLLABORATION ON A BACKHOE BUCKET

When it comes to customer and industry benefits, the 2022 Casting of the Year checks nearly all the boxes: Conversion from another process? Check. Reshored manu...

-

Choosing the Right Stainless Steel Forging Manufacturer: Key Factors to Consider

Discover applications (construction, medical) and qualities of a good supplier (expertise, customization).

-

The significance of gearbox in industrial applications

Gear systems are integral to a wide range of industrial applications, from automotive to manufacturing machinery. Within these systems, the gear housing...