Methods for Assessing 3D Printing Accuracy

Author: SAIVS Date Published: May 20,2024

3D Printing offers incredible potential for creating complex and functional objects. However, ensuring the printed parts match the intended design requires careful consideration of dimensional accuracy. This article delves into the key concepts of accuracy, precision, and tolerance in 3D printing. We explore the factors that influence the dimensional accuracy of printed parts and provide practical methods for achieving high-precision results.

I. Defining Accuracy, Precision, and Tolerance

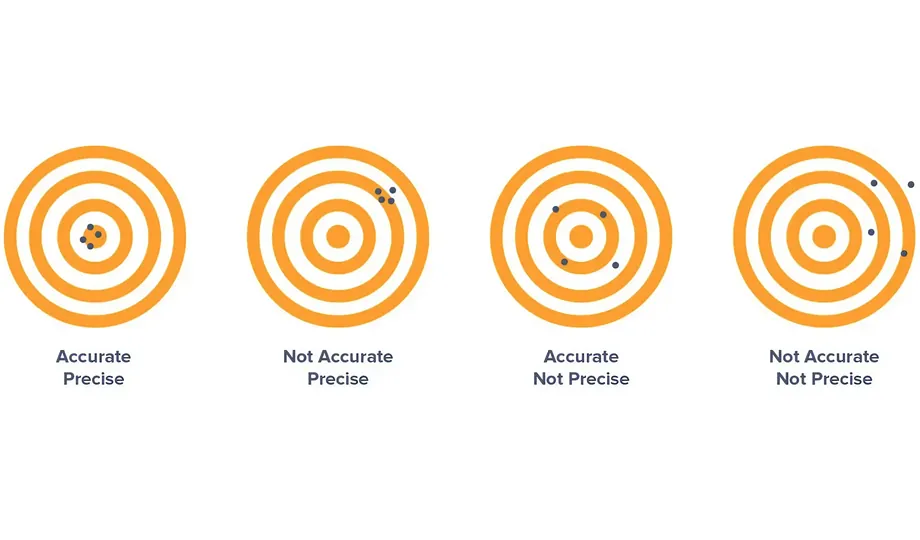

Accuracy: How closely a measurement aligns with the true value. In 3D printing, this refers to how well the printed part matches the dimensions specified in the CAD model.

Precision: The repeatability of a measurement. In 3D printing, it reflects the consistency of dimensional outcomes across multiple prints of the same model.

Tolerance: The acceptable range of deviation from the nominal dimension. It defines the permissible level of variation in a part's size.

II. Factors Influencing Dimensional Accuracy

3D Printing Technology: Different technologies offer varying levels of inherent accuracy. Generally, resin-based methods (SLA and DLP) achieve higher precision compared to FDM printing.

Materials: Thermal properties like shrinkage and expansion coefficients of materials impact final dimensions. ABS, for example, exhibits higher shrinkage rates, making it more prone to warping. Material flowability and formability also play a role.

Print Parameters: Print settings like layer height, printing temperature, and cooling rate significantly influence accuracy. Optimizing these parameters for the chosen technology and material is crucial.

Environmental Conditions and Printer Stability: Fluctuations in ambient temperature, humidity, and printer vibrations can affect print accuracy. Maintaining a controlled environment and ensuring printer stability are essential.

Model Design: The geometry and features of the model can impact accuracy. Slender features, thin walls, and sharp corners can lead to warping and shrinkage. Designing for manufacturability is important.

III. Methods for Improving Dimensional Accuracy

Model Design Optimization: Avoid features that might cause warping or shrinkage, such as slender elements, thin walls, and sharp corners.

Print Parameter Adjustment: Select appropriate print parameters based on the 3D printing technology and material being used. Refer to manufacturer recommendations and experiment for optimal settings.

Employing Support Structures: Utilize support structures when necessary to prevent part deformation during printing. These temporary structures help maintain proper geometry, especially for complex features.

Post-Processing Techniques: Certain 3D printing methods can benefit from post-processing techniques like polishing or machining to achieve higher dimensional accuracy.

IV. Impact of Warping and Shrinkage

Warping: Deformation of a part during the printing process, often caused by uneven cooling or internal stresses. It can lead to deviations from intended dimensions.

Shrinkage: Reduction in dimensions of the part as it cools and solidifies after printing. This inherent property of materials can affect final accuracy.

V. Dimensional Accuracy of Different 3D Printing Technologies

Stereolithography (SLA) ±0.1 - 0.3 mm

Digital Light Processing (DLP)±0.1 - 0.3 mm

Selective Laser Sintering (SLS)±0.3 - 0.5 mm

Multi Jet Fusion (MJF)±0.3 - 0.5 mm

Fused Deposition Modeling (FDM) ±0.5 - 1.0 mm

VI. Influence of Materials on Dimensional Accuracy

The thermal properties of materials significantly impact dimensional accuracy. Materials with high shrinkage coefficients, like ABS, are more prone to warping and require careful selection of print parameters. Additionally, material flowability and formability characteristics can influence accuracy. Materials with higher viscosity may lead to non-uniform material flow, resulting in dimensional deviations.

VII. Measurement of Dimensional Accuracy

3D Scanners: High-precision 3D scanners can be employed to accurately measure the dimensions of 3D printed parts.

Comparison with CAD Model: Comparing the dimensions of the CAD model to the actual printed part using calipers or micrometers can assess dimensional accuracy.

Conclusion

Dimensional accuracy in 3D printing is a complex interplay of factors, including the chosen technology, materials, print parameters, environmental conditions, and model design. Through meticulous planning, design optimization, and proper process control, users can achieve high-precision 3D printed parts for diverse applications.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

The common production problem and analysis of die casting moulds

Expanding on the Provided Information and Incorporating Additional InsightsCommon Die Casting Mould Production Problems and AnalysisMolten Metal Splash (Ru

-

An Overview Of Green Sand Casting

Introducing Green Sand CastingCasting metals in foundries as a mold is done with green sand, a material that is a compound mixture of sand and cement. It is kno...

-

The significance of gearbox in industrial applications

Gear systems are integral to a wide range of industrial applications, from automotive to manufacturing machinery. Within these systems, the gear housing...

-

Shaft Components: The Best Choice For CNC Machining

From solid to hollow, delve into CNC machining precision, uncovering routes from turning to drilling.

-

How to improve the quality of gear forgings

How to improve the quality of gear forgings? Shanghai Zhiyuan Flange Forging Co., Ltd. pointed out that hardness is an important quality inspection index for he...

-

Key Factors Affecting the Quality and Accuracy of Investment Casting

Investment casting is a versatile and widely used casting process that can produce highly precise and complex parts with excellent surface finish and dimensio...