Optimizing Low Pressure Casting Process for Aluminum Alloy Car Wheels

Author: SAIVS Date Published: Jun 23,2025

Optimizing the Low-Pressure Casting Process for aluminum alloy Car Wheels

With the growing global demand for durable and lightweight automotive components, aluminum alloy wheels have become a preferred choice in the automobile industry. Known for their superior strength-to-weight ratio, corrosion resistance, and aesthetic appeal, these wheels are often manufactured using low-pressure casting techniques. This article explores how to optimize the casting process to enhance product quality, reduce defects, and improve overall production efficiency.

Advantages of Aluminum Alloy Wheels

Aluminum alloy wheels offer significant advantages over traditional steel wheels. The lightweight nature of aluminum helps reduce vehicle weight, thereby improving fuel efficiency and driving performance. In addition, Aluminum Alloys provide excellent corrosion resistance and thermal conductivity, making them ideal for high-performance vehicles.

By adding elements like magnesium and copper, the mechanical properties of aluminum alloys can be significantly enhanced. These intermetallic compounds improve hardness and structural integrity, essential for safety and performance on the road.

Structural and Thermal Considerations in Casting

Understanding the behavior of aluminum alloys under different thermal conditions is critical. During casting, improper temperature control can lead to incomplete dissolution of alloying compounds, resulting in internal voids and lower hardness. Therefore, precise temperature management is essential to form a uniform microstructure with optimal mechanical properties.

Repair Technology in Casting

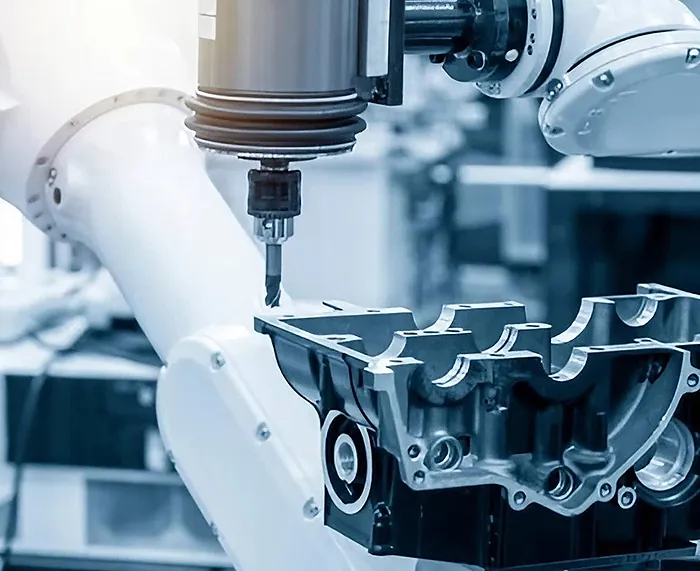

Post-casting repair techniques such as grinding, milling, and reshaping are used to improve surface finish and correct defects. However, if overused or poorly executed, these repairs may weaken the structural integrity. Controlled and step-by-step repair is key to maintaining product safety and appearance.

Low-Pressure Casting: Principles and Applications

Low-pressure casting involves filling molds with molten aluminum alloy using controlled pressure in a sealed environment. This technique minimizes turbulence and reduces the chances of air entrapment and porosity. It is widely used in the manufacturing of automotive wheels due to its high production efficiency and quality output.

Challenges and Defect Prevention

Despite its benefits, low-pressure casting can lead to defects such as shrinkage cavities, cold shuts, and misruns if not properly managed. Common causes include outdated molds, incorrect pressure settings, and inappropriate temperature control. These challenges necessitate process optimization.

Strategies for Process Optimization

1. Upgrade Mold Systems: Replacing old molds with modern, high-precision molds ensures consistency and better product quality.

2. Adopt Advanced Equipment: Incorporating automated and intelligent casting equipment improves control over pressure and temperature, enhancing repeatability and reducing manual errors.

3. Train Skilled Technicians: A well-trained workforce ensures better process control. Hiring qualified technical personnel and investing in continuous training helps in sustaining quality and innovation.

4. Implement Quality Monitoring: Continuous monitoring of key parameters like mold filling speed, melt temperature, and pressure curve allows for early detection and correction of anomalies.

Conclusion

Optimizing the low-pressure casting process of aluminum alloy wheels not only improves product performance and durability but also elevates a company's competitive edge in the global market. With the right combination of advanced technology, skilled personnel, and process control, manufacturers can meet the increasing demand for high-quality automotive wheels while reducing defects and improving efficiency.

As a professional manufacturer and supplier, our company offers precision low-pressure cast aluminum alloy wheels tailored to client specifications. contact us to discuss your OEM or bulk procurement needs.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

CNC vs. Rapid Prototyping: Which Machining Process is Right for You?

CNC vs. Rapid Prototyping: Choosing the Best Machining Process for Your NeedsIn the fast-evolving world of manufacturing, choosing the right machining proc

-

Exploring Die-Cast Prototyping Methods: Six Effective Strategies

Die casting is a manufacturing process used to create metal parts with high precision and excellent surface finish.When it comes to prototyping for die-cast par...

-

How Printing Choices and Design Enhance the Strength of Your 3D Prints

This passage discusses factors that influence the tensile strength of 3D printed parts.

-

How to Reduce Costs on CNC Prototyping

Even for one-off prototypes, sometimes parts still need to be machined (rather than using other methods). This may be due to certain material requirements

-

How to shell stainless steel Investment casting?

The production process of stainless steel investment castings is relatively complex, and the requirements for dimensional accuracy are high. The shell making pr...

-

AN INNOVATIVE DIE CAST METHOD

AN INNOVATIVE DIE CAST METHODDoes your part design require external gears or threads where a parting line would significantly affect the part performance?We kno...