Unlocking the Future of Manufacturing with Advanced Aluminum Alloy Die Casting Technologies

Author: SAIVS Date Published: Apr 07,2025

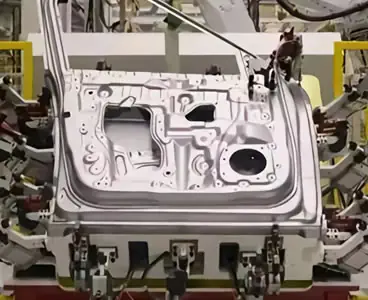

In the era of high-performance manufacturing, aluminum alloy Die Casting has emerged as a cornerstone technology that drives innovation across industries—from automotive and aerospace to electronics and industrial machinery.

Over the past few decades, particularly since the 1990s, China has transformed its die-casting industry into a global powerhouse, with Ningbo saivs Machinery Co., Ltd. at the forefront of this dynamic growth.

A Rapidly Growing Industry

With more than 3,000 die-casting enterprises, China's production capacity for die-cast parts has soared from 266,000 tons in 1995 to 870,000 tons by 2005, maintaining an annual growth rate of over 20%. Impressively, aluminum alloy die-casting products make up over 75% of this total output. As demand rises, so too does the need for advanced, high-quality equipment and processes—areas where Ningbo SAIVS stands out.

Aluminum Alloy: The Preferred Choice

Aluminum alloy is not just lightweight and corrosion-resistant—it also offers excellent machinability and thermal conductivity, making it an ideal material for automotive parts, electronics casings, telecom components, lighting fixtures, and more. SAIVS offers a wide range of die-casting solutions that utilize high-strength aluminum alloy series such as Al-Si, Al-Si-Cu, and Al-Zn to meet diverse industrial demands.

Technological Advancements in Die Casting

1. Vacuum Die Casting

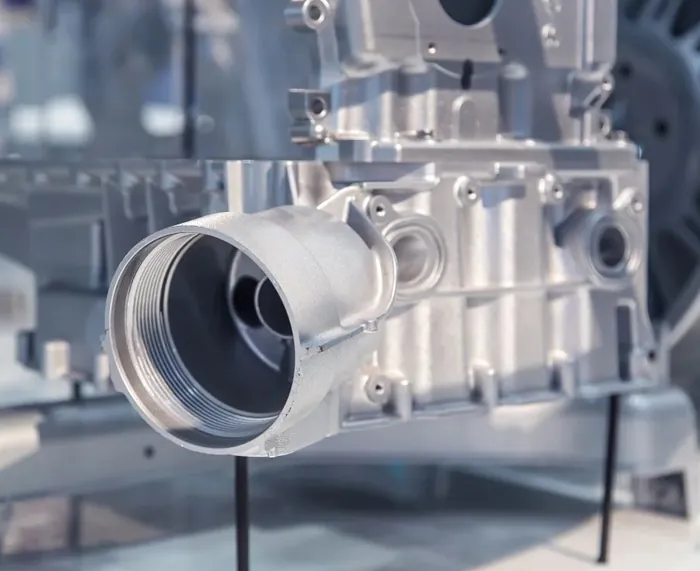

By removing air from the die cavity, vacuum die casting reduces porosity and enhances the mechanical strength of the finished part. This method is critical for parts requiring high air-tightness or heat treatment, such as automotive transmission housings and hydraulic valve bodies.

2. Oxygen-Filled Die Casting

A cutting-edge technology that uses oxygen to replace nitrogen and hydrogen in the die cavity, reducing defects and improving product density. This method results in stronger, more durable components that can undergo welding or heat treatment without performance loss.

3. Semi-Solid Die Casting

This revolutionary approach involves casting partially solidified metal, resulting in parts with superior mechanical properties and minimal shrinkage. SAIVS integrates both rheocasting and thixocasting techniques to deliver high-precision, high-strength castings for next-gen applications.

4. Squeeze Die Casting & Electromagnetic Pump Casting

Squeeze casting minimizes porosity and maximizes strength, while electromagnetic pump low-pressure casting ensures clean, turbulence-free metal flow. These methods are ideal for producing high-performance components used in electric vehicles and industrial equipment.

Superior Equipment, Unmatched Performance

SAIVS has heavily invested in R&D and production capabilities. Our die-casting machines range from compact models under 3000kN for smaller applications to massive 30000kN systems for large structural components. Key features include:

High-speed cold-chamber injection systems (up to 10m/s)

Automated loading, spraying, and trimming systems

Real-time computer-controlled injection monitoring

Uniform acceleration injection systems for consistent part quality

All of these technologies ensure that our equipment delivers superior casting performance, long service life, and minimized downtime—giving you the production edge you need.

Die Casting Mold Excellence

Modern die casting molds demand durability, precision, and consistency. SAIVS uses high-performance materials like H13 and imported 8407 steels, ensuring our molds withstand extreme thermal and mechanical stress. We also employ CAD/CAM/CAE simulations to design and optimize mold performance, cutting lead times and boosting product quality.

Future Outlook & Strategic Direction

As the automotive, telecommunications, and consumer electronics sectors continue to grow, the demand for high-performance die-cast aluminum parts will only increase. At SAIVS, our mission is to provide cutting-edge die casting technology tailored to the evolving needs of global manufacturers. Our focus for the future includes:

Developing colorable and environmentally-friendly Aluminum Alloys

Expanding high-strength and heat-resistant alloy offerings

Enhancing rapid prototyping and concurrent engineering capabilities

Continuing our leadership in semi-solid and vacuum die casting systems

Partner with SAIVS to elevate your production with our advanced aluminum alloy die casting solutions. Whether you're looking to streamline operations, enhance product quality, or innovate your next-generation component designs, we offer the equipment and expertise to make it happen.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

CNC vs. Rapid Prototyping: Which Machining Process is Right for You?

CNC vs. Rapid Prototyping: Choosing the Best Machining Process for Your NeedsIn the fast-evolving world of manufacturing, choosing the right machining proc

-

Forging and stamping: the current status of automobile stamping technology

The modern automotive industry demands ever-increasing production scale, multi-model compatibility, and large, integrated body panels. Traditional rigid, s

-

How to Categorize Scrap Steel for Foundry Use?

Comprehensive Guide to Scrap Steel Classification and Distinctions in the Foundry IndustryUnderstanding the classification and proper handling of scrap ste

-

How to ensure the quality of die castings

This article will introduce how to ensure the quality of die casting from the machine and equipment, material selection, process control, testing standards, and...

-

Factors Affecting the Dimensions of Stainless Steel Castings

Learn about the factors affecting dimensional accuracy, including material expansion and deformation, and understand why choosing an experienced foundry like SA...

-

Optimizing Low Pressure Casting Process for Aluminum Alloy Car Wheels

Optimizing the Low-Pressure Casting Process for Aluminum Alloy Car WheelsWith the growing global demand for durable and lightweight automotive components,