Understanding 3D Printing Technologies and Inspection Methods

Author: SAIVS Date Published: Jun 28,2024

Introduction

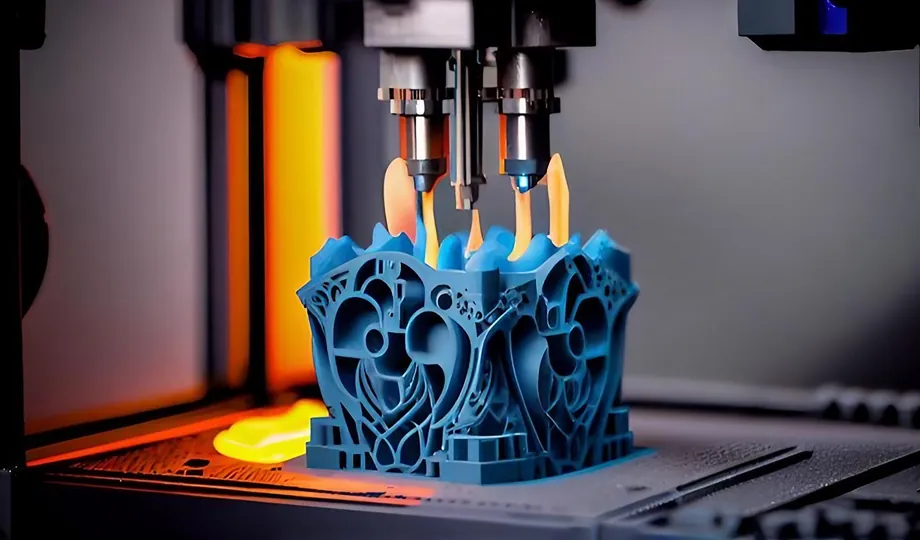

3D Printing, also known as additive manufacturing (AM), revolutionizes how objects are created. This technology builds objects layer-by-layer using various methods and materials. This article explores seven main categories of 3D printing and the inspection methods used to guarantee the quality and reliability of printed parts.

Main Categories of 3D Printing Technology

Metal Extrusion (FDM/FFF):

This method dispenses material through a nozzle, building objects layer by layer. It works with various materials like thermoplastics, metals, and even food. Leading providers include Stratasys, MakerBot, and Ultimaker.

Material Jetting:

Here, inkjet heads deposit droplets of building material onto a powder bed. This allows complex, multi-material objects. It's suitable for photopolymers, waxes, and even metals. Major providers are 3D Systems and Stratasys.

Binder Jetting:

Similar to material jetting, a binding agent glues powder particles together instead of building material. This method works with materials like metals, sand, and ceramics. Leading providers include 3D Systems and ExOne.

Sheet Lamination:

This technology bonds sheets of material (paper, metal) to create 3D objects. Providers include Helisys and Fabrisonic.

Vat Photopolymerization (SLA/DLP): This method uses light to cure liquid resin into a solid object. It's limited to photopolymers but offers high accuracy. Leading providers include 3D Systems and Envisiontec.

Powder Bed Fusion:

This method uses lasers or electron beams to melt powder particles together, creating a solid object. It works with polymers, metals, and sand. Major providers are EOS and SLM Solutions.

Directed Energy Deposition (DED):

This method uses a laser to melt and fuse materials as they are deposited. It's ideal for repairing or modifying existing metal parts. Leading providers include Optomec and Trumpf.

Inspection Methods for 3D printed parts

To ensure quality, manufacturers use various non-destructive testing (NDT) methods to inspect parts without damaging them. Common NDT techniques include:

- Visual inspection

- CT scans

- X-ray

- Leak testing

- Eddy current testing

- Mechanical property testing

- Metallography

- Hardness testing

These NDT methods are crucial for:

Identifying defects

Monitoring material properties

Checking dimensions

Guaranteeing part quality

New 3D Printing Inspection Method

Dr. Ben Dutton is developing Laser Ultrasound technology for NDT inspections in the additive manufacturing sector at the Manufacturing Technology Center in Coventry, UK. This technology can evaluate powder beds during direct deposition processes and inspect components with complex structures. Laser Ultrasound can detect imperfections just below the surface, unlike traditional camera methods limited to surface photos. This ability to penetrate deeper layers makes Laser Ultrasound a superior inspection method for identifying potentially fatal flaws.

Conclusion

Understanding 3D Printing Technologies and implementing effective inspection methods are essential for producing high-quality parts and advancing the field of additive manufacturing.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

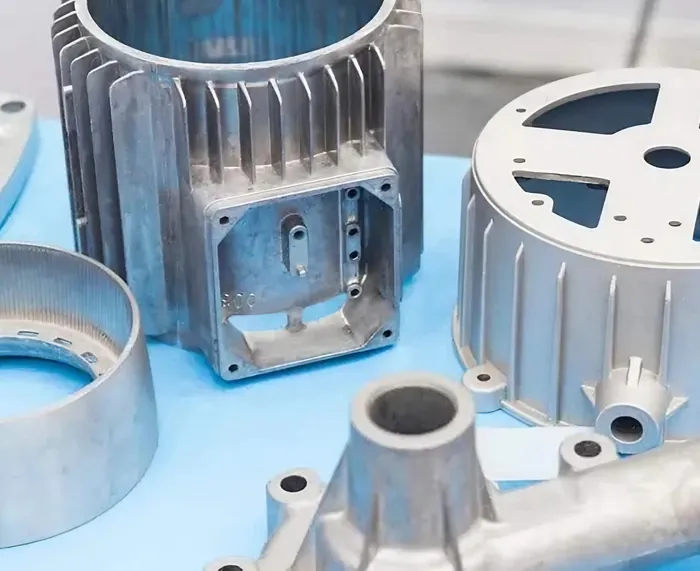

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Methods for Assessing 3D Printing Accuracy

Ensure your 3D prints meet specifications! Explore various methods for measuring dimensional accuracy, including 3D scanners, calipers, and micrometers.

-

Why Stainless Steel Casting Wins in Food Machinery Parts

Discover why it‘s the secret weapon for hygiene, durability & performance in food processing.

-

Design Considerations for Aluminum Die Casting

Aluminum die casting is a widely used manufacturing process for producing complex, high-precision parts. Manufacturers achieve excellent dimensional accura

-

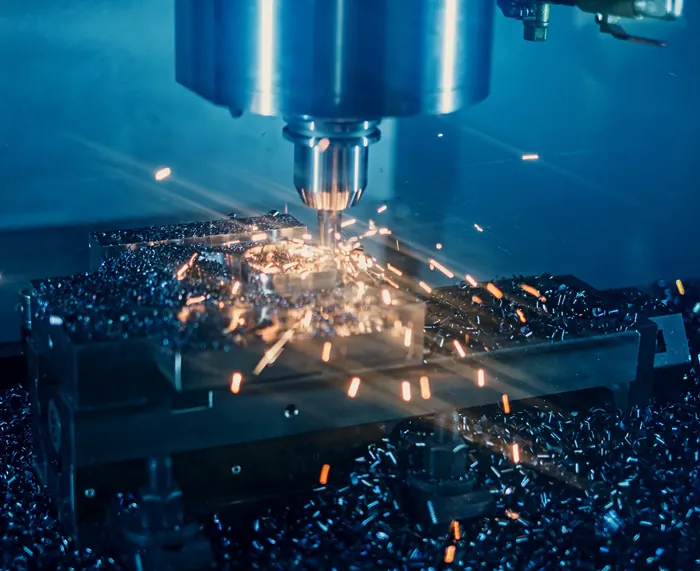

Safety Guidelines for Precision CNC Machining

This comprehensive guide covers training, PPE, machine maintenance, proper setup, emergency procedures, and more to ensure a safer and more efficient manufactur...

-

Optimizing Tool Materials for Efficient Cast Iron Machining

In the competitive landscape of the machinery industry, improving processing technology and increasing efficiency are crucial for reducing overall costs. O

-

Choosing the Right Stainless Steel Forging Manufacturer: Key Factors to Consider

Discover applications (construction, medical) and qualities of a good supplier (expertise, customization).