Advanced Strategies to Extend the Life of Aluminum-Magnesium Die-Casting Molds — SAIVS Best Practices

Author: SAIVS Date Published: Aug 11,2025

How saivs Improves the Service Life of Aluminum-Magnesium Die-Casting Molds

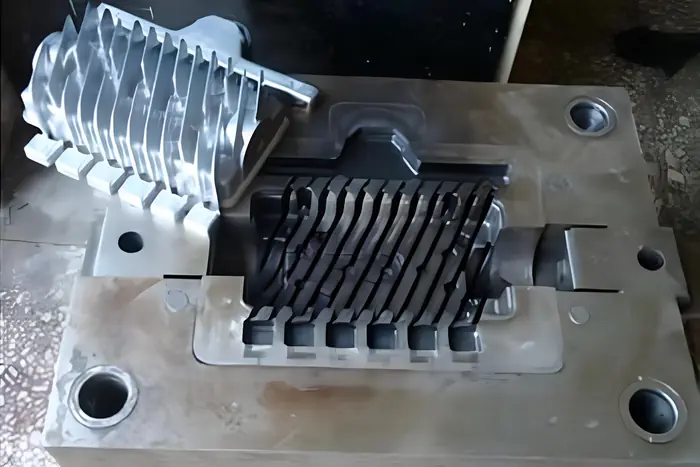

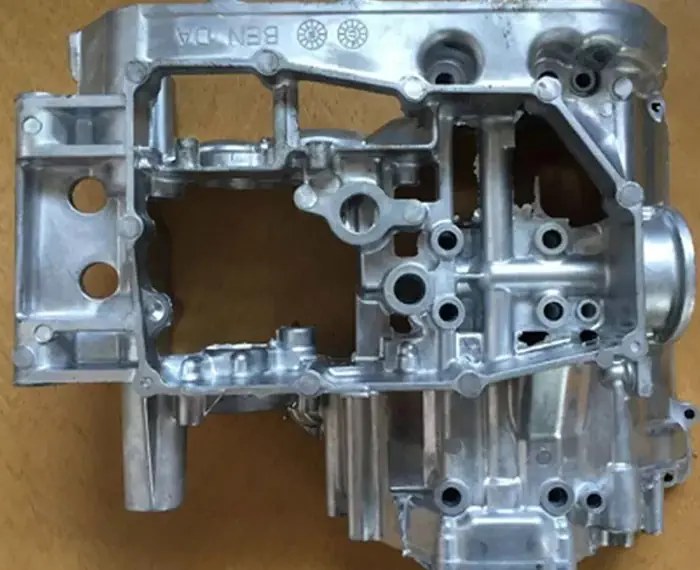

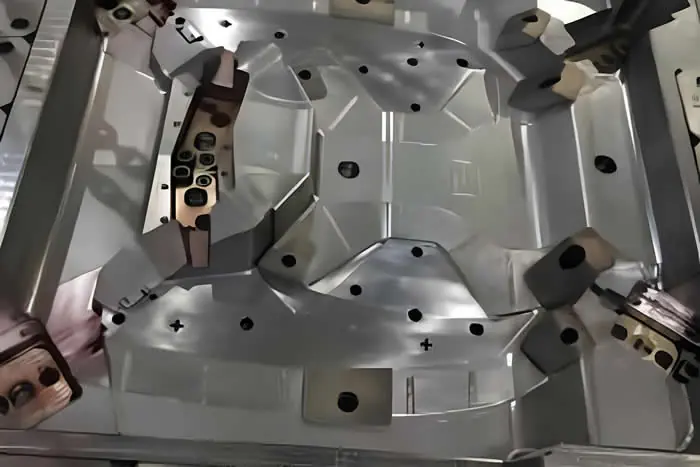

Aluminum-magnesium die-casting molds operate in extremely aggressive thermal and chemical environments.

To protect tooling investment and increase productivity, SAIVS applies a systems approach that combines correct steel selection, precision heat treatment, and surface strengthening.

This article summarizes practical failure modes, recommended mold steels, heat-treatment workflows, and cost-effective surface treatments that directly translate to longer mold life and lower per-part tooling cost.

Common Failure Modes and Why They Matter

Understanding failure modes is the first step toward mitigation.

Mold sticking, erosion, thermal fatigue, wear, and catastrophic fracture are the primary failure mechanisms seen in aluminum-magnesium die-casting.

Each failure mode originates from specific stressors — chemical adhesion at the interface, high-velocity particle impact, rapid thermal cycling, surface softening, or stress concentration in complex geometries.

By mapping these failure drivers to targeted countermeasures, SAIVS helps customers choose the right combination of materials and processes for their production conditions.

Mold Sticking

Sticking happens when local contact stresses exceed the yield strength of the cavity surface, causing micro-welding between the molten alloy and the steel.

Frequent anti-stick coating applications and wide temperature swings aggravate the problem.

Mitigation: choose steels with high surface hardness after nitriding and maintain controlled cavity temperatures to minimize adhesion and shear damage.

Erosion and Impact Pitting

Molten metal with entrained oxides and gas bubbles causes repeated micro-impacts on the mold surface, forming pits that grow into fatigue cracks.

Mitigation: improve gating and vent design to reduce turbulence, and use steels with high hot-strength and carbide stability to resist micro-pitting.

Thermal Fatigue and Wear

Rapid heating and cooling cycles create thermal stresses and surface softening that initiate cracks and accelerate wear.

Mitigation: reduce the temperature differential through effective preheating, optimize cycle times, and apply surface treatments that retain hardness at working temperatures.

Steel Selection: Match Material to Duty Cycle

Choosing the right die steel is a business decision that balances upfront tooling cost against lifetime and downtime.

SAIVS recommends a set of proven steels for aluminum-magnesium applications, selected for hardenability, thermal strength, toughness, and resistance to molten metal corrosion.

Recommended Steels (Typical Uses)

3Cr2W8V (H21) — ideal for high-load cavities where high tempering stability and wear resistance are required.

4Cr5MoSiV1 (H13) — an industry workhorse with superior toughness and thermal fatigue resistance for general-purpose die-casting.

4Cr5Mo2MnSiV1 (Y10) — enhanced thermal stability and molten metal corrosion resistance for aggressive casting mixes.

4Cr3Mo3SiV (H10) and 3Cr3Mo3VNb (HM3) — for high-temperature wear resistance and secondary tempering hardening where extended life is critical.

Heat Treatment Best Practices

A precise heat-treatment schedule converts a good steel into an exceptional tool.

SAIVS employs controlled pre-heat, hierarchical quenching, and staged tempering to balance core toughness and surface hardness.

Pre-heat and Normalizing

Continuous annealing or isothermal annealing helps produce a uniform granular pearlite or spheroidized carbide distribution before final hardening.

For complex shapes, isothermal annealing reduces internal stress and improves machinability prior to quenching.

Quenching Strategies

Quench temperatures must match the alloy system — e.g., H13 typically 1020–1100°C and 3Cr2W8V 1050–1150°C.

Use stepped or gas quenching for complex, high-deformation parts to lower cracking risk.

Immediately follow quench cooling with tempering at controlled temperatures to avoid hardness collapse.

Tempering and Surface Strengthening

Tempering determines final hardness and thermal fatigue resistance.

For many aluminum-magnesium molds the working hardness target is in the 42–48 HRC range, adjusted by quench and tempering history.

To further boost surface life without sacrificing core toughness, SAIVS applies nitrocarburizing or gas nitriding processes that raise surface hardness above 800–900 HV while retaining a ductile core.

Production Controls and Maintenance That Extend Life

Material and process choices deliver the baseline life; production controls ensure that life is realized.

SAIVS advises strict cavity temperature control, optimized coating schedules, routine inspection for micro-pitting, and a documented preventive maintenance cycle to avoid unexpected downtime.

Why Buy from SAIVS

SAIVS integrates metallurgy, heat-treatment expertise, and production engineering to deliver molds that run longer and produce more good parts per tooling dollar.

Our technical evaluations match mold steel, heat treatment, and surface strengthening to your alloy, cycle time, and part geometry.

Contact SAIVS for an application review and receive a tailored recommendation that reduces scrap, shortens cycle downtime, and lowers total cost of ownership.

Call to action: Contact SAIVS technical sales to request a mold life assessment and compare predicted life and payback for upgraded steels and surface treatments.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

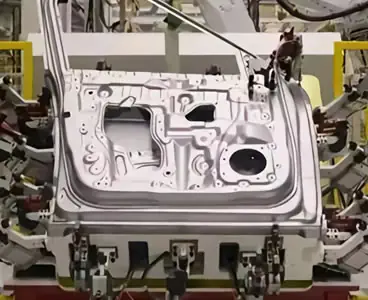

Forging and stamping: the current status of automobile stamping technology

The modern automotive industry demands ever-increasing production scale, multi-model compatibility, and large, integrated body panels. Traditional rigid, s

-

Safeguarding Product Reliability: Penetrant Testing and Ultrasonic Flaw Detection for Castings

This article delves into casting defects, their impact on product quality, and two key non-destructive testing methods: penetrant testing (PT) and ultrasonic fl...

-

Why Investment Casting Is Cruial In The Railway Sector

The railway industry is one of the most important sectors in the world, with an extensive network of tracks and trains that transport goods and people across lo...

-

How To Calculate Pressure Die Casting Tonnage

Calculation FormulaThe calculation formula for the selection of die-casting machine: Die-casting machine clamping force (t) = 1.4 * casting projected area

-

Choosing a Stainless Steel Foundry: Key Factors to Consider

Stainless steel casting is a manufacturing process that involves pouring molten stainlesssteel into a mold to create a desired shape or component. It is a versa...

-

Why Multi-Station Progressive Dies Are Essential for Precision Metal Stamping

Why Multi-Station Progressive Dies Are Essential for Precision Metal StampingIn the field of modern metal manufacturing, the demand for high-efficiency, hi