Advanced Surface and Internal Quality Inspection Methods for Castings — Reliable NDT Solutions from SAIVS

Author: SAIVS Date Published: Oct 27,2025

Advanced Surface and Internal quality Inspection Methods for Castings

Overview:

Accurate inspection of castings is essential to ensure product performance, safety, and long-term reliability.

Surface and internal defects must be detected and characterized using the appropriate inspection techniques so that corrective actions and quality guarantees can be applied before parts enter service.

saivs provides a full suite of nondestructive testing (NDT) equipment and services tailored for ductile iron, steel, and non-ferrous castings.

1. Surface and Near-Surface Defect Detection

1.1 Liquid Penetrant Testing (PT)

Liquid penetrant testing is the fastest, lowest-cost method to reveal surface-opening defects such as cracks, laps, and pinholes.

The process uses a low-viscosity penetrant that soaks into openings on the casting surface, followed by removal of excess penetrant and application of a developer to draw out the trapped material and create a visible indication.

Color contrast penetrants are widely used for routine inspection, while fluorescent penetrants combined with ultraviolet lamps deliver higher sensitivity in darkened inspection areas.

Surface finish strongly affects sensitivity — the smoother the surface (for example, ground or machined), the smaller the detectable discontinuities.

1.2 Magnetic Particle Testing (MT)

Magnetic particle testing is ideal for ferromagnetic castings to reveal surface and shallow subsurface discontinuities.

By magnetizing the part and applying magnetic particles in dry powder or wet suspension form, leakage fields at defects attract the particles and form visible indications.

To maximize detection coverage, SAIVS technicians use multiple magnetization directions and calibrated yokes or coil setups so that defects of all orientations can be exposed.

1.3 Eddy Current Testing (ECT)

Eddy current testing is a high-speed electromagnetic method for detecting surface and near-surface flaws up to several millimeters deep.

ECT is particularly effective on conductive castings and can be implemented with portable handheld probes or automated scanners for production-line inspection.

Limitations include less intuitive sizing and shape display compared to radiography, but ECT excels where speed, no-contact testing, and surface conductivity characterization are required.

2. Internal Defect Detection

2.1 Radiographic Testing (RT)

Radiographic testing using X-rays or gamma rays produces an image of internal structure and is particularly powerful for detecting porosity, shrinkage, inclusions, and complex discontinuities.

RT delivers a visual record, showing defect shape, number, and planar distribution; however, depth localization typically requires multiple exposures or computed tomography (CT) techniques.

Micro-focus X-ray systems and digital radiography have improved image sharpness and workflow efficiency, enabling faster inspection and improved defect characterization for small and complex castings.

SAIVS supplies both conventional film-based RT services and digital radiographic solutions to fit lab and on-site needs.

2.2 Ultrasonic Testing (UT)

Ultrasonic testing uses high-frequency sound waves to interrogate internal volumes and is especially effective for thick-section castings where radiography may be less practical.

UT can detect planar cracks, voids, and inclusions and provides depth information and positional accuracy when operated with appropriate scan techniques and calibrated reference blocks.

Advanced UT methods such as phased-array ultrasonic testing (PAUT) and time-of-flight diffraction (TOFD) greatly improve sizing accuracy and defect characterization and are part of the SAIVS inspection toolbox for demanding components.

3. Complementary Methods and Practical Considerations

3.1 Vibration Testing and Other Techniques

Vibration testing can detect changes in modal response caused by internal damage or porosity in assembled parts and is often used as a supplemental screening tool in production lines.

Other techniques such as visual inspection, dimensional measurement, chemical composition analysis, and mechanical testing remain essential for a full Quality Control program.

3.2 Selection Criteria for NDT Methods

Choosing the correct inspection method depends on material type, casting wall thickness, expected defect type, production rate, and sensitivity requirements.

For surface-breaking defects on smooth-finished parts, liquid penetrant and magnetic particle inspections are the most sensitive and cost-effective.

For volumetric defects in thick castings, radiography and ultrasonic testing (particularly PAUT and TOFD) provide the best coverage and quantitative information.

4. SAIVS Advantage — Equipment, Expertise, and Procurement

Turnkey NDT Solutions:

SAIVS offers a complete range of inspection instruments — from penetrant kits and magnetic particle equipment to eddy current testers, digital radiography systems, and phased-array ultrasonic scanners.

We provide calibrated instruments, certified inspectors, and tailored inspection procedures aligned with international standards to help you meet specification and regulatory requirements.

Why Buy from SAIVS:

Purchasing NDT equipment and inspection services from SAIVS guarantees documented traceability, technical support, and training so your shop floor can implement robust quality control workflows.

Our service packages include on-site setup, procedure development, personnel certification support, and preventative maintenance to keep inspection systems producing reliable results.

5. Practical Tips for Buyers and Quality Engineers

5.1 Define Inspection Objectives

Before selecting equipment, clearly define what defect types and sizes must be detected, the production throughput, and whether recordable images or real-time inspection is required.

5.2 Combine Methods for Best Coverage

Use surface methods (PT, MT, ECT) for high-sensitivity detection of opening defects and volumetric methods (RT, UT) for internal porosity and shrinkage.

5.3 Invest in Training and Procedure Development

Even the best instruments underperform without qualified operators and documented procedures aligned with casting specifications.

SAIVS provides training and procedure templates to accelerate capability building and reduce inspection variability.

Conclusion

Optimizing casting quality requires a layered inspection strategy that pairs surface-sensitive methods with volumetric NDT techniques.

SAIVS delivers both the hardware and the technical expertise to set up effective inspection programs — helping manufacturers reduce scrap, prevent field failures, and accelerate time to market.

Contact SAIVS for a consultation, Customized quotes, and NDT solutions designed specifically for your casting types and production environment.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

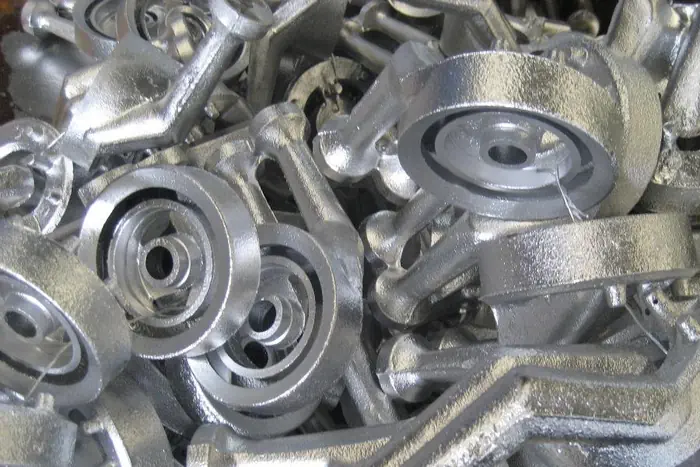

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Nickel-Based Alloy Casting: Superior Corrosion Resistance

What is Nickel-Based Alloy Casting?Nickel-based alloys are metallic materials that primarily consist of nickel,but they also include various other elements such...

-

Die cast product design: 3 considerations

Die casting is a manufacturing process used to produce metalcomponents with high precision and efficiency. It involves injecting molten metal into a die, which ...

-

Understanding Investment Casting Molds: A Step-by-Step Guide

This paper describes the key steps involved in making investment casting molds and emphasizes the importance of quality control measures in the process.

-

Advanced Surface Treatments to Improve Aluminum Die Casting Performance

Advanced Surface Treatments to Improve Aluminum Die Casting PerformanceIn aluminum alloy die casting, the surface quality of the final product directly imp

-

Rapid Injection Molding: A Guide to Fast-Track Production

Rapid injection molding offers fast, cost-effective production of plastic parts in low to medium volumes. Learn about the process, advantages, disadvantages, an...

-

Automatic Deburring Technology in Die Casting: Improving Efficiency and Product Quality

Introduction to Automatic Deburring in Die CastingDie casting is a high-efficiency metal forming process widely used for aluminum alloy parts in automotive