Automatic Deburring Technology in Die Casting: Improving Efficiency and Product Quality

Author: SAIVS Date Published: May 19,2025

Introduction to Automatic Deburring in Die Casting

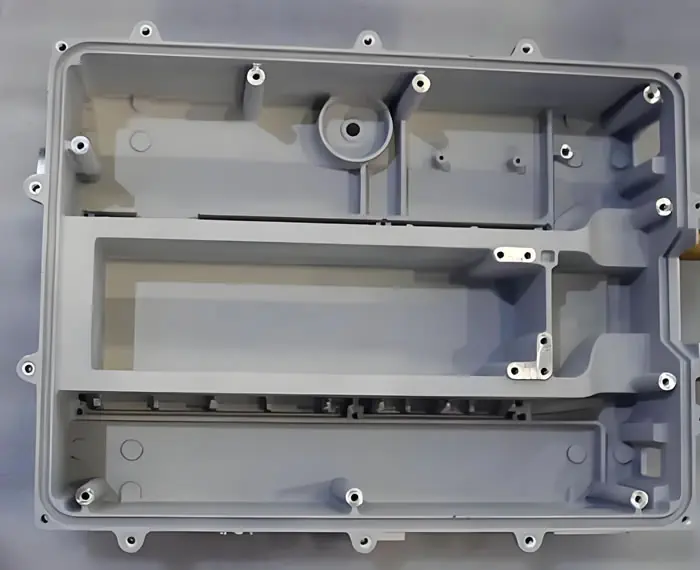

Die casting is a high-efficiency metal forming process widely used for aluminum alloy parts in automotive, machinery, and electronic industries.

However, the process often leaves burrs—undesirable projections on castings that affect product performance and appearance.

Traditionally removed by manual labor, burr removal is now being revolutionized by automated deburring technology, which improves consistency,

reduces labor cost, and enhances product quality.

Challenges of Manual Deburring

Labor-Intensive and Costly

Manual deburring operations typically require 1–2 times more workers than die casting itself. In addition, the harsh working environment—characterized by dust, noise, and repetitive strain—makes it hard to hire and retain young workers. This leads to unstable production capacity and increasing labor costs.

Inconsistency in Product Quality

Manual operations are subject to human error. This often results in:

- Inconsistent burr removal

- Incomplete cleaning of hard-to-reach burrs

- Damage to the part surface

Such variations negatively affect downstream processing, assembly precision, and customer satisfaction.

The Rise of Automatic Deburring

Advantages of Automation

- High precision: Automated tools and robots can remove burrs with micron-level accuracy.

- Consistent results: Every part receives the same treatment, improving quality consistency.

- Efficiency: A five-axis machining center or robot can replace 2–3 manual workers, reducing cycle time and boosting output.

- Reduced rework: Consistent deburring means fewer defects and returns.

Integration with Machining Centers

Machining centers are increasingly being used for burr removal because of their:

- High torque and cutting power

- Fast tool change capabilities

- Better adaptability to complex geometries

These features allow machining centers to integrate deburring as part of the machining process, improving overall workflow efficiency.

Robot Deburring Capabilities

Equipped with belt machines, grinders, and pneumatic tools, robots can effectively:

- Remove parting line burrs

- Clean ejector pin traces

- Polish external surfaces

- Access internal holes <2mm with specialized reamers

Over 90% of burrs can be reliably removed this way.

Burr Characteristics and Formation Mechanism

Sources of Burrs in Die Casting

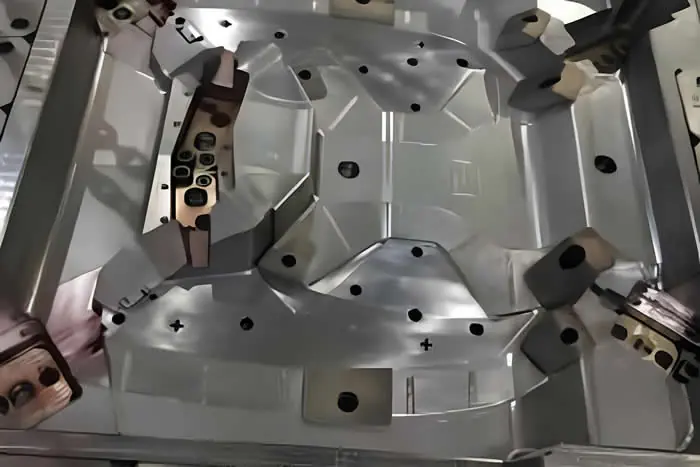

- Die Casting Machine: Inadequate clamping force results in mold gaps.

- Mold design and Quality: Poor tolerance control in parting surfaces and ejector pins.

- casting process: Excessive aluminum temperature or pressure causes flash formation.

Burr Types

- Parting Line Burrs: Along mold parting surfaces.

- Process-Induced Burrs: From gates, overflows, or ejector marks.

- Crack Burrs (Turtle Burrs): Caused by thermal or mechanical fatigue of the mold.

Impact of Mold Gap on Burr Size

- Gap ≥ 0.09mm: Clearly formed burrs, hard to remove.

- Gap 0.07–0.08mm: 2–4mm burr length, moderate removal difficulty.

- Gap ≤ 0.06mm: Powder-like burrs, easily removed by shot blasting.

Maintaining mold gap below 0.07mm is critical for automated burr recognition and removal.

Establishing Burr Removal Standards

Burr Appearance Grades

- Class I: Mirror-polished or decorative surfaces – burr size ≤ 0mm

- Class II: Functional surfaces – burr ≤ 0.2mm

- Class III: Invisible or non-critical areas – burr ≤ 0.4mm

Standardization Benefits

Standardized burr expectations:

- Guide robot programming and tool path design

- Simplify quality inspection

- Avoid excessive tool wear or downtime from unmanageable burrs

Tool Selection and Application

- Pneumatic Reamer: Ideal for internal holes and gates

- Grinding Machine: For line burrs, typing marks, and surface polishing

- Belt Sander: Best for edge burrs and tortoise cracks

Combined with automation, these tools help achieve up to Class I appearance for most parts.

Best Practices for Automated Deburring

Control of Mold and Casting Parameters

- Mold parting gap

- Casting shrinkage compensation

- Aluminum alloy temperature

- Injection speed and pressure

Batch and Process Management

- Use batch management to control mold wear

- Track casting process parameters that influence burr consistency

- Store data for traceability and continuous improvement

Conclusion: Embrace Automation for Die Casting Excellence

Whether your company is dealing with wheel hubs, enclosures, brackets, or structural die-cast parts, adopting automated deburring is the future-proof way to:

- Improve productivity

- Reduce costs

- Achieve consistent quality

- Meet customer appearance expectations

Companies must define clear burr standards, control tolerance and mold design, and invest in high-precision automation to stay competitive in the global die-casting market.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Why Investment Casting Is Crucial In the Aerospace Industry

Investment casting, also known as lost-wax casting, is a process that involves creating a wax model of the desired part, coating it with a ceramic material, and...

-

Optimizing Shell Body Die Casting Process for Superior Quality and Efficiency

IntroductionIn the realm of automotive and machinery manufacturing, the demand for high-precision, durable, and complex-shaped components is ever-increasin

-

Why Multi-Station Progressive Dies Are Essential for Precision Metal Stamping

Why Multi-Station Progressive Dies Are Essential for Precision Metal StampingIn the field of modern metal manufacturing, the demand for high-efficiency, hi

-

Grain Structure: The Touchstone of Sheet Metal Processing Technology

This article delves into the role of grains in sheet metal processing, the unpredictability of metal sheets, and proposes optimization strategies to improve par...

-

Technical Requirements for Investment Casting

Throughout the production process, precision casting solidifies its liquid immediately at room temperature and pours the compound into its unique die casting di...

-

Gravity Die Casting: Choosing the Right Alloy for Your Needs

Gravity die casting is a manufacturing process that uses gravity to fill a mold with molten metal. This process is used to produce a wide variety of metal compo...