How Metal Oxide Films Affect the Quality of Aluminum Alloy Castings

Author: SAIVS Date Published: May 12,2025

aluminum alloy casting is a critical process in modern manufacturing, widely used in automotive, aerospace, construction,

and industrial machinery. However, an often underestimated factor significantly influencing the quality and performance of these castings

is the formation and behavior of metal oxide films during the casting process. At Ningbo saivs Machinery Co., Ltd.,

we take oxide film control seriously to ensure the delivery of premium aluminum alloy castings to our global clientele.

When aluminum is melted, it naturally reacts with oxygen in the atmosphere, forming a layer of aluminum oxide (Al₂O₃) on the molten surface.

This oxide film has a much higher melting point and is more stable than the aluminum itself.

Its slightly higher density allows it to stay suspended in the melt instead of separating or floating away.

When the melt is disturbed—whether during furnace pouring, ladling, high-velocity gas treatments,

or degassing operations—this oxide film is folded into the liquid metal, forming what researchers such as Professor J. Campbell refer to as bi-films.

These oxide film interlayers, once introduced into the molten metal, become embedded within the final casting structure and lead to a range of serious defects.

Macroscopic effects include the induction of pores, micro-shrinkage, and internal crack initiation points that compromise mechanical integrity. Microscopically,

oxide films disrupt grain refinement, affect dendritic structure formation, and reduce the efficiency of modifying elements like sodium and strontium—key for enhancing the properties of Al-Si alloys.

Even more critically, these oxide films provide ideal nucleation sites for gas porosity, particularly hydrogen.

As the temperature drops during solidification, hydrogen solubility in the aluminum alloy decreases.

In the presence of oxide films, small amounts of air trapped between the folded film layers become perfect vacuums for hydrogen diffusion.

This accelerates the formation of pinhole porosity and significantly weakens the structural integrity of the final part.

Without oxide films, even alloys with higher hydrogen content would often solidify without defects.

In casting theory, creating a new gas phase (e.g., a hydrogen bubble) in a homogeneous molten metal requires significant surface energy,

which is typically unavailable under normal cooling conditions.

Therefore, in clean alloys without oxide films, pore nucleation is theoretically and practically difficult.

This highlights the fact that oxide films are not just passive contaminants—they are active initiators of defects.

Furthermore, the role of bi-films in feeding-related defects such as shrinkage porosity must not be overlooked.

During solidification shrinkage, voids tend to form in areas where oxide films are present, as these films are hollow, fragile, and easily pulled apart.

As a result, castings with uncontrolled oxide content exhibit significantly higher rates of internal cracking, shrinkage holes, and porosity.

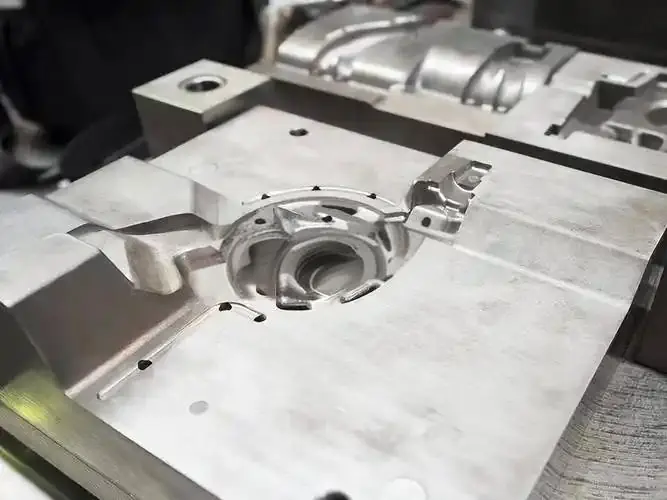

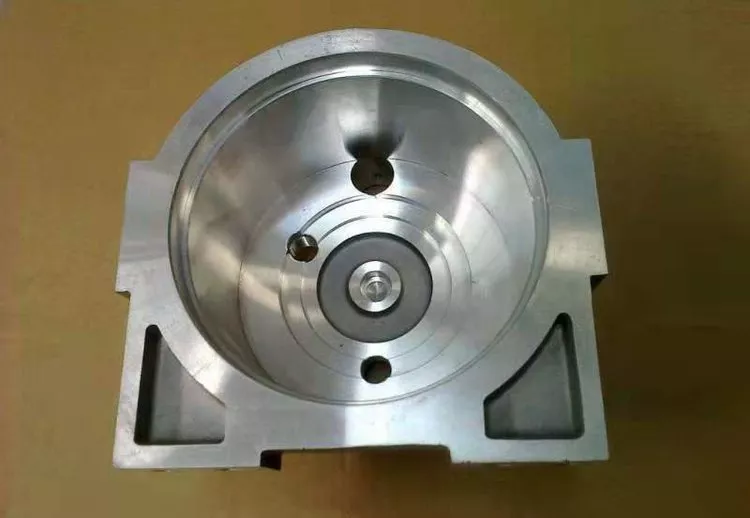

At Ningbo Saivs Machinery Co., Ltd., our advanced casting protocols are designed to minimize oxide film formation at every stage.

From alloy smelting in clean, inert environments to controlled pouring systems and low-turbulence mold filling,

every step is optimized to limit surface disturbance and prevent oxide film folding. Additionally, we employ rigorous degassing and filtration techniques,

but we also recognize that purification alone is not enough—eliminating oxide film entrainment is equally, if not more, important.

By partnering with Saivs Machinery, you're not only sourcing high-performance aluminum castings—you’re choosing a supplier that understands and controls the root causes of internal casting defects. This results in parts with improved mechanical strength, enhanced fatigue resistance, and longer operational life, especially crucial in industries with zero tolerance for failure.

Whether you require OEM Aluminum Casting parts, custom prototype services, or volume manufacturing for critical applications, Saivs Machinery provides industry-leading expertise, precision, and consistent quality to meet your needs.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Solutions to Common Problems in Die Casting Production

Solutions to Common Problems in Die Casting ProductionIn the process of die casting production, various issues may arise that can impact production efficie

-

The Process Of Gravity Die Casting

Gravity Die Casting Process1. Die Preparation:The initial stage of gravity die casting involves preparing the die, which is a high-quality mold made from steel ...

-

How to Prevent Shrinkage in Die Castings

At present, the application of impregnation technology in the products of die-casting aluminum manufacturers is constantly expanding. China advocates for full i...

-

Choosing the Right Material for Investment Casting

What is Investment casting?Investment casting is a metalworking process that involves creating a shape, called the investment, out of wax or other materials. Th...

-

Investment casting: a comparison between stainless steel and aluminum

Investment casting is a widely used manufacturing process that allows the production of complex and intricate metal components with high dimensional accuracy. W...

-

The Six Key Benefits of Lost Foam Casting

In the ever-evolving landscape of manufacturing, selecting the right casting method is crucial for efficiency and cost-effectiveness. Lost foam casting has