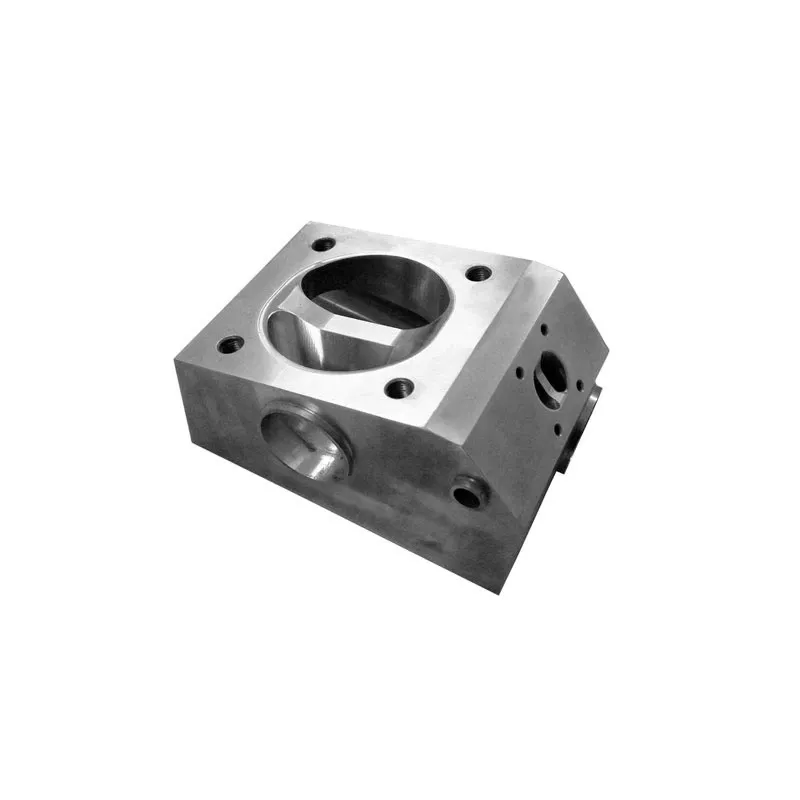

Precision Quality Control & Mold Design for High-Performance Die-Cast Aluminum Parts

Author: SAIVS Date Published: Sep 01,2025

Quality Control of Raw Materials for Die-Casting aluminum alloy Parts

Raw materials determine the baseline quality of every die-cast aluminum component produced by saivs.

Strict incoming inspection and documented acceptance criteria are the first line of defense against defects.

Sampling for chemical composition of the main alloy elements must be routine and traceable.

Only when raw material certificates and lab tests match the specification should material be accepted into production.

Critical Alloy Elements to Monitor

Iron (Fe): Excess iron promotes brittleness and cracking, while too little iron can create mucous films and demolding problems.

Control iron content within the engineered window for the selected alloy to balance strength and ductility.

Copper (Cu): Moderate copper improves fluidity, strength, and hardness but excessive copper reduces plasticity and raises hot-cracking risk.

Manganese (Mn): Manganese refines iron intermetallics and mitigates iron’s negative effects, but over-addition can encourage segregation.

Zinc (Zn) & Silicon (Si): Zinc enhances fluidity and machinability; silicon supports high-temperature formability—both must be controlled to avoid porosity or poor finishing.

Recycled Material Management

Returned material and furnace returns must be cleaned and segregated before reuse.

Limit the ratio of recycled material to new metal to avoid degrading casting quality; do not exceed one-third recycled in the charge.

Maintain batch records for recycled inputs to trace any downstream issues back to source material.

Mold design and Manufacture: Gates, Overflows and Exhaust

Mold geometry governs metal flow, pressure distribution and ultimately the internal soundness of the casting.

Design decisions must be validated early through trials and adjusted to the specific part geometry.

Inner Gate and Overflow Groove

Gate cross-section controls filling speed, pressure and shear; an optimized gate ensures consistent cavity fill.

A wider gate with reduced thickness can improve flow at higher speeds, but gate design must match the casting contours and machine dynamics.

For large or complex sections, provide overflow grooves to prevent vortices and trap oxides before they become internal defects.

Exhaust Slot Strategy

Gas entrapment is the primary cause of porosity in die-cast parts, so exhaust design is essential.

Place exhaust grooves where flow stagnation or high gas volume is expected and keep exhaust gaps controlled to prevent metal washout.

A practical guideline is to maintain exhaust groove gaps below 0.20 mm to balance venting with splash control.

Design multiple small vents across the parting lines and use core—parting intersections to channel gases out rapidly.

Using the Parting Surface and Core for Venting

Leverage the natural gaps at parting lines and core interfaces as supplementary exhaust paths.

Design controlled micro-gaps to release gas while avoiding flash or excessive die wear.

Cavity Materials, Surface Finish and Heat Treatment

Select cavity and core steels for thermal stability and wear resistance based on production volume and alloy melting point.

Increase draft angles, use generous transition fillets and specify surface finish values that ease demolding and reduce local stress risers.

Apply suitable heat treatment and finishing to cavities and cores to extend service life while keeping risks of early cracking low.

Conservative machining may reduce initial failures but can shorten tool life; balance processing with planned maintenance and process optimization.

Control of Mold Temperature

Mold temperature dramatically affects flow, solidification and surface quality.

Cold molds tend to trap defects; overly hot molds cause demolding difficulty and thermal cracking.

Establish target cavity temperatures for each alloy and part geometry, monitor with sensors located in representative heat-dissipation zones, and stabilize temperature before running production.

Well-controlled thermal management reduces scrap and improves dimensional and mechanical consistency.

Conclusion & SAIVS Production Advantage

Improving die-cast aluminum quality demands disciplined raw material control, intelligent mold design, precise venting, and consistent thermal management.

SAIVS combines material traceability, engineering-driven gate and exhaust design, and robust mold material strategies to raise first-pass yield and reduce rework.

If your project requires precision die-cast aluminum components with verifiable quality processes, contact SAIVS for technical support, prototype trials, and production quotes.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Die Casting Temperature Control: Improve Casting Quality and Production Efficiency

Die casting mold temperature affects casting quality and productivity. Learn how to control temperature for optimal casting.

-

How can riserless casting be achieved in nodular iron production?

Achieving Riser-Free Casting in Nodular Cast Iron: Key Conditions and TechniquesNodular cast iron, also known as ductile iron, is a material highly valued

-

The Excellence of Sand Casting for Gearbox Housings

Why cast iron gearbox housings made by sand casting are ideal for strength, durability and complex designs.

-

Brief analysis of the characteristics and advantages of aluminum die casting

Briefly analyze some characteristics and advantages of aluminum die casting.Aluminum die casting is a very popular manufacturing method in the process of produc...

-

Unveiling The Secrets Of Stainless Steel Gearboxes

About the definition, advantages, and maintenance of steel gearbox products.

-

why zinc die casting is used for automotive components

The zinc die casting process is widely used for making components in industrial and building sectors, but the most common application of it is in the automotive...