Smart Die Casting Quality Control: CT-Driven CAE Feedback to Improve Yield URL Slug

Author: SAIVS Date Published: Oct 09,2025

Smart Die Casting Quality Control: CT-Driven CAE Feedback to Improve Yield

Die casting remains a cornerstone manufacturing process for automotive, aerospace, and electronics components.

At saivs, we position modern die casting as a digitally enabled production line where precision, speed, and closed-loop control deliver measurable commercial advantages.

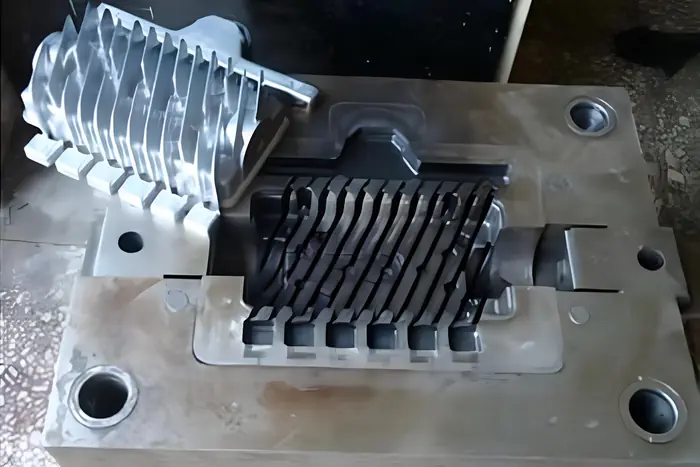

Why Die Casting Is Ideal for Digital Automation

Die casting operates at high pressure and high speed, producing near net shape, thin-walled alloy parts with excellent repeatability.

Because the process is highly cyclical and environment-bound, it is particularly well suited to automation of machine islands and centralized monitoring.

Real-time data collection from each machine enables predictive maintenance, tight process control, and consistent part quality — all critical to reducing scrap and accelerating customer acceptance.

mold temperature control — A Simple, High-Impact Example

One foundational control loop is mold temperature management.

As molten metal repeatedly fills a cold-chamber cavity the mold temperature rises and must be stabilized to avoid surface defects and premature die wear.

SAIVS integrates temperature sensors, flow controllers, and PID feedback to control coolant temperature and flow rate so the mold reaches and maintains thermal balance.

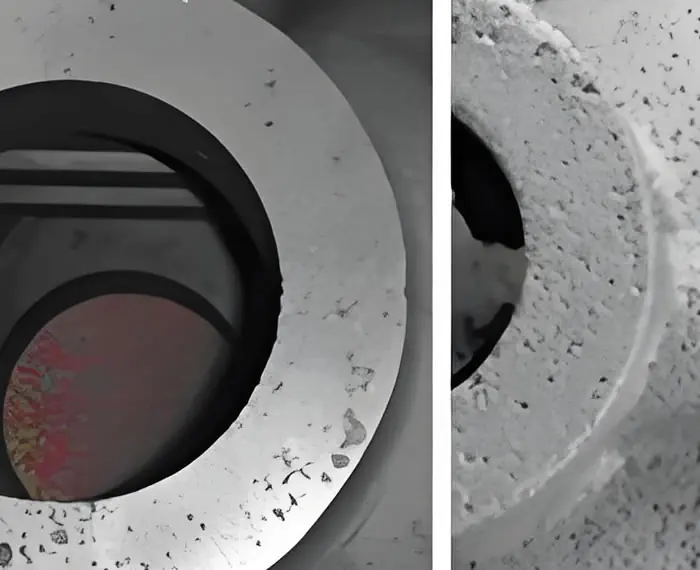

From 2D Spot Checks to 3D CT Inspection

Traditional quality inspection relies on destructive cut checks or 2D X-ray slices sampled from batches.

These methods compress three-dimensional defects into limited two-dimensional views and miss many internal porosity and inclusion patterns.

Industrial computed tomography (CT) changes the game by providing full 3D imaging of internal structures so density, porosity and entrainment can be quantified for each part.

SAIVS incorporates high-speed CT inspection into production lines to capture the three-dimensional defect map necessary for reliable automated decision making.

Speed, Accuracy, and Software Throughput

To be useful on a production line CT scanners must be fast, produce analysis-grade images, and feed results to recognition software without creating bottlenecks.

SAIVS systems prioritize high throughput scanning protocols paired with optimized reconstruction algorithms so inspection keeps pace with the die-casting cycle.

CAE: The Engine of Process Feedback and Correction

Three-dimensional defect data from CT is only the first half of the solution.

The second half is rapid, accurate analysis and a corrective action plan driven by CAE (computer-aided engineering) simulation.

CAE models simulate filling, solidification, and heat transfer to identify likely hot spots, shrinkage cavities, and flow-related entrainment.

When CT detects a recurring porosity pattern, SAIVS routes the 3D data to the CAE analysis center which evaluates the root cause and proposes parameter adjustments.

This closed-loop — detect, analyze, correct, and verify — reduces trial-and-error on the shop floor and accelerates the window to consistent production.

Automating CAE Recommendations

While CAE has historically required human interpretation, SAIVS focuses on solidifying repeatable CAE responses into parameterized corrective actions.

Where appropriate, these actions can be pushed automatically to machine controllers, cooling systems, or gating modifications to remove the defect source quickly.

Practical Benefits for Buyers and Specifiers

What does this mean for procurement managers and engineers choosing a supplier or line equipment?

Lower scrap rates and fewer mechanical reworks translate to direct cost savings and faster time to market.

Consistent internal quality increases the likelihood of meeting stringent OEM acceptance criteria and reduces the risk of late rejections or warranty exposure.

SAIVS’s integrated solution — combining automated die-casting islands, high-speed CT inspection, and CAE feedback — is designed to help you scale production while protecting quality.

Faster Ramp-Up, Measurable KPIs

By instrumenting machines and inspection points, SAIVS delivers actionable KPIs: first pass yield, porosity distribution statistics, cycle-to-cycle temperature stability, and more.

These KPIs make performance visible to operations, quality, and purchasing teams and support continuous improvement programs with hard data.

How SAIVS Supports Your Buying Decision

SAIVS offers modular implementation paths depending on your plant maturity and budget.

For greenfield factories we provide fully integrated die-casting islands with embedded cooling control and inspection gateways.

For retrofit projects we supply CT integration packages, edge analytics appliances, and CAE consulting that convert existing lines into digitally controlled cells.

All solutions include commissioning support, process validation runs, and training so your team can interpret CT results and act on CAE recommendations immediately.

Immediate Next Steps

Request a process audit to map how CAE simulation and CT inspection can be inserted into your current workflow.

SAIVS will produce a phased plan showing ROI, expected yield improvement, and capital requirements so you can compare scenarios objectively.

Contact SAIVS today for a quotation and a technical roadmap tailored to your die casting part family and production volumes.

Ningbo Saivs Machinery Co.,ltd.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Effective Strategies to Prevent and Solve Subcutaneous Porosity in Castings

Measures to Prevent and Solve Subcutaneous Porosity in CastingsSubcutaneous porosity in castings is a common defect caused by various factors in the castin

-

Repairing Defects in Investment Castings

From the defect causes to repair methods, a comprehensive analysis of investment casting defects repair knowledge, help you to understand the casting process.

-

X-ray detection of internal defects in die castings

Aluminum castings are widely used in industries such as automotive parts, mechanical manufacturing, computers, electronics, medical equipment, watch instruments...

-

Working Principle and Characteristics of Die Casting Technology

Die-casting technology is the process of organically combining and applying three production elements of die-casting, namely, die-casting alloy, die-casting die...

-

Advanced Strategies to Extend the Life of Aluminum-Magnesium Die-Casting Molds — SAIVS Best Practice

How SAIVS Improves the Service Life of Aluminum-Magnesium Die-Casting MoldsAluminum-magnesium die-casting molds operate in extremely aggressive thermal and

-

How CNC Machining Is Changing the Medical Industry

Digital motors, sophisticated software, and specialized cutting tools are yielding precision, repeatability, and scalability in CNC machining.Products, devices,...