Sequence of Investment Casting Technology

Author: SAIVS Date Published: May 16,2023

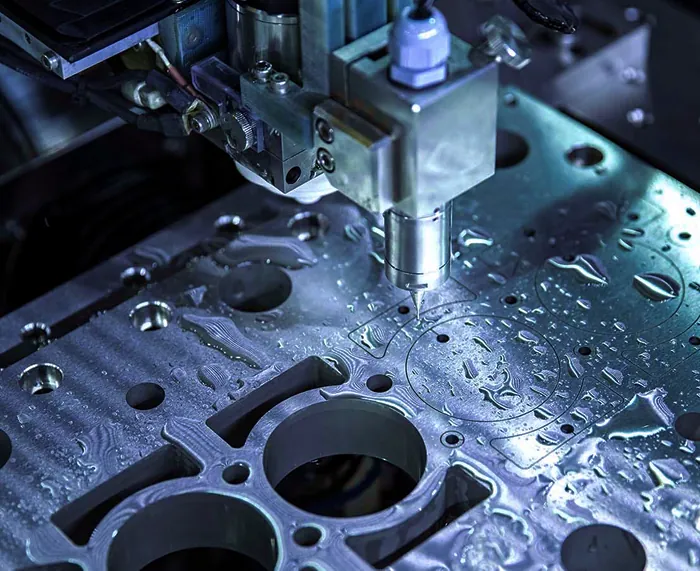

Each mode of production has its own production sequence. Actual operators must produce in accordance with their production sequence, rather than in disorder, which will cause certain damage to the goods produced or product quality problems. Precision die machining is one of them, so what is the sequence of parts machining for precision mechanical equipment? Let me tell you.

1. The reasonable layout of Investment Casting support processing should be considered according to the structure and blank condition of the part and the requirement of accurate positioning and clamping. The key is that the bending strain of the product and commercial workpiece is not damaged.

1. The whole production process of road production process can not impair the accurate positioning of the whole process of next production process and the production process of practical parts clamping the boundary line should also be considered comprehensively.

2. First terminate the inner wall plus production process, then the design and Manufacturing Process.

3. In order to reduce the frequency of continuous accurate positioning, tool change and nut movement in investment casting process, the connection is terminated by the same accurate positioning, clamping method or the production process of the same knife manufacturing.

4. During the whole process of multiple production stops in the same equipment, proper layout is required to reduce bending strain damage of investment casting joint products and commercial workpieces.

2. Centralized sequencing method of CNC blades: i.e. dividing the production process according to common CNC blades and producing parts with the same CNC blade. In other parts that can be carried out with two or three knives. Unnecessary accurate positioning deviations can reduce tool change frequency and shorten air transport time.

Sequencing of production and manufacturing parts:

Many components related to production and manufacturing content can be divided into production and manufacturing parts according to their structural characteristics, such as shape, design, steep slope or plan. Mr. General production plan design, accurate positioning surface, and then production of manufacturing holes; Mr. A. produces simple appearance and complex graphics for reproduction and processing. Processing high-precision parts first and then high-precision parts.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

What are the requirements of aluminum alloy die casting for the function of die steel?

1. High tempering resistance and cold and hot fatigue resistance of aluminum alloy die-castingMany aluminum alloy die-casting dies produced continuously should ...

-

How to Categorize Scrap Steel for Foundry Use?

Comprehensive Guide to Scrap Steel Classification and Distinctions in the Foundry IndustryUnderstanding the classification and proper handling of scrap ste

-

5 CNC Machining Materials

AluminumAluminum is one of the most popular materials for CNC machining due to its excellent machinability, lightweight nature, and resistance to corrosion

-

Why Aluminum Reigns Supreme in Telecom Enclosure Evolution

Explore the pivotal role of die-cast aluminum in telecom enclosures, providing a lightweight, strong, and thermally efficient solution for today‘s digital infra...

-

What are the requirements for precision die casting?

Precision Die Casting: A Superior Metal Forming TechnologyPrecision die casting is a cutting-edge manufacturing process that allows for the creation of int

-

Advantages and precautions of aluminum alloy gravity casting?

The thickness of the outer wall of aluminum alloy castings in the process of gravity casting is called wall thickness, which is an important factor in the proce...