SAIVS:Custom CNC Precision Machining Suppliers

Author: SAIVS Date Published: Dec 28,2023

Introduction

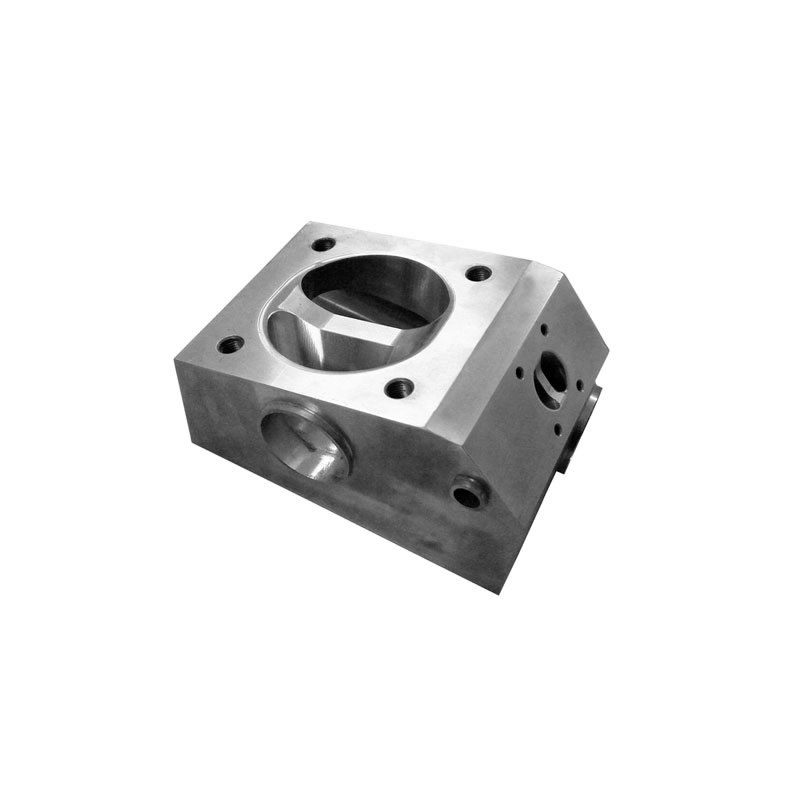

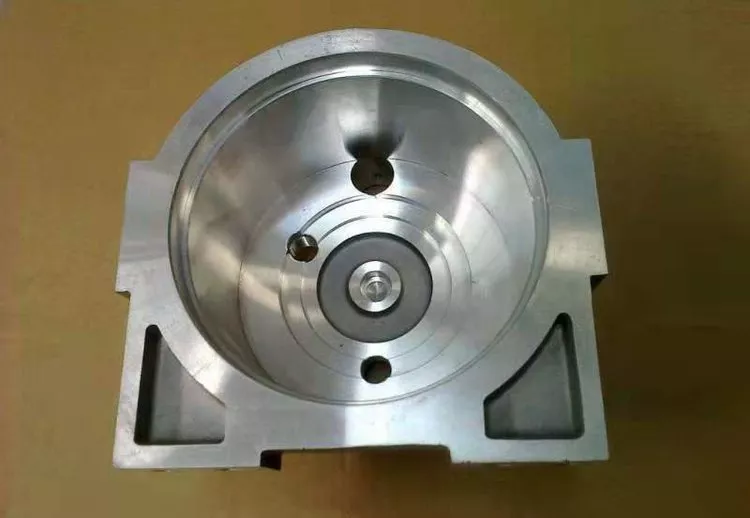

In the realm of modern manufacturing, CNC machining reigns supreme. This cutting-edge process employs computer-controlled tools

to sculpt and shape materials with unparalleled precision and accuracy. From simple geometries to intricate patterns,

CNC machining breathes life into diverse designs, catering to a vast array of industries.

I. What is CNC Machining?

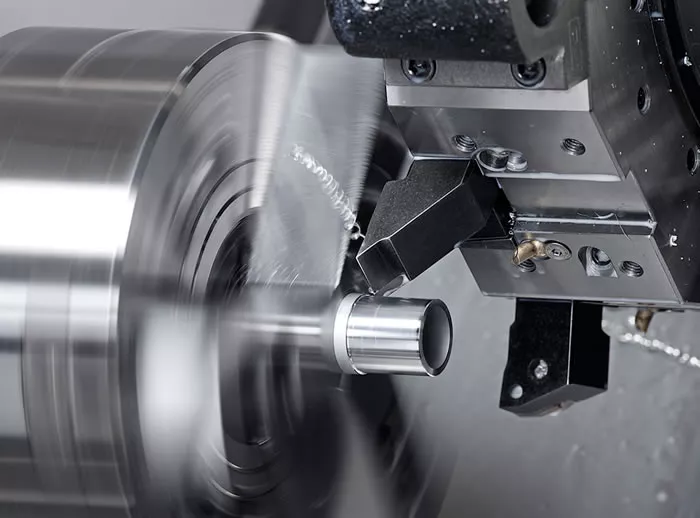

CNC machining uses a computer to control the movement of a cutting tool. The computer is programmed with the desired shape of the part,

and the cutting tool follows the programmed path. This allows CNC machines to create parts with high precision and accuracy.

II. Benefits of CNC Machining

Unmatched Accuracy: CNC machines achieve tolerances as tight as 0.0001 inches, crucial for demanding applications like aerospace and medical devices.

Repeatable Precision: Once programmed, CNC machines flawlessly replicate parts, ideal for mass production and maintaining consistent quality.

Versatile Manufacturing: From metals and plastics to wood and composites, CNC machines handle a diverse range of materials,

catering to various industry needs.

Enhanced Efficiency: Automation streamlines the production process, minimizing waste and maximizing output compared to traditional machining methods.

III. Applications of CNC Machining

CNC machining is used in a wide variety of industries, including:

Aerospace: Fabricating critical aircraft components like engines, wings, and fuselages.

Automotive: Producing high-performance car parts like engines, transmissions, and body panels.

Medical: Creating life-saving medical devices such as implants, prosthetics, and surgical instruments.

Manufacturing: Building a wide range of tools, dies, molds, and other production equipment.

IV. saivs CNC Machining Materials

SAIVS CNC machining services offer a wide range of materials to meet diverse manufacturing needs.

Some commonly used materials include:

Brass: Alloy of copper and zinc (typically 60-80% copper, 40-20% zinc)

Available types: HPb59-1, H59, H62, H68, H80, H90, etc., as well as copper.

Aluminum: Silver-white light metal (typically aluminum alloyed with magnesium, silicon, and other elements)

Available types: AL6061, AL6063, AL7075, AL5052, AL6082, etc.

stainless steel: Iron-chromium alloy with at least 10.5% chromium (often containing additional elements like nickel, molybdenum, and others)

Available types: SS201, SS301, SS303, SS304, SS316, 420, etc.

Plastics: Wide variety of synthetic polymers with diverse properties.

Available types: PVC, POM, NYLON, etc. (Please note, many other plastic types are available with specific properties for various applications).

Custom CNC Precision Machining Suppliers

At SAIVS, we leverage cutting-edge technology and skilled craftsmanship to deliver exceptional CNC machining services. We specialize in:

High-Precision Machining: Achieving tolerances as low as 0.0001 inches, exceeding industry standards for accuracy.

Complex Geometry Machining: Mastering intricate 3D shapes and freeform surfaces, bringing your most challenging designs to life.

Mass Production Expertise: Scaling up production with efficiency and consistency, ensuring high-quality components for large-scale projects.

Customized Solutions: Tailoring our services to your specific needs, offering expert guidance and flexibility to meet your unique requirements.

Embrace the Power of CNC Machining with SAIVS

Whether you're a seasoned engineer or a budding entrepreneur, SAIVS is your trusted partner in bringing your vision to reality.

Contact us today and experience the transformative power of precision CNC machining.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How to shell stainless steel Investment casting?

The production process of stainless steel investment castings is relatively complex, and the requirements for dimensional accuracy are high. The shell making pr...

-

Brief analysis of the characteristics and advantages of aluminum die casting

Briefly analyze some characteristics and advantages of aluminum die casting.Aluminum die casting is a very popular manufacturing method in the process of produc...

-

How to Prevent Shrinkage in Die Castings

At present, the application of impregnation technology in the products of die-casting aluminum manufacturers is constantly expanding. China advocates for full i...

-

Process of CNC Rapid Prototyping

CNC Rapid Prototyping, also known as CNC-RP, is a process that combines computer numerical control (CNC) machiningwith rapid prototyping techniques to quickly p...

-

Selecting Metals For Various Die Casting Methods

Die casting is a manufacturing process used to shape metal and produce complex metal parts using reusable molds called dies. Die casters utilize a die casting m...

-

The Benefits of Using CNC Machining in Manufacturing

CNC machining is a process used to create high-precision metal components in various industries. In this article, we will explore the benefits of using CNC mach...