Unlocking Diversity: 3 Types of Sand Molds Commonly Used in Sand Casting

Author: SAIVS Date Published: Mar 25,2024

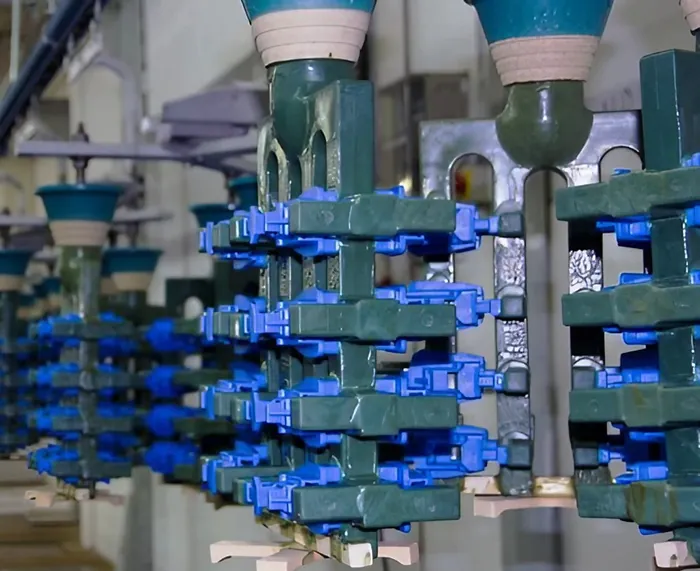

Sand Casting is a metal casting process that uses sand molds to produce metal castings.

The sand mold is made of sand and a binder, which can be clay, sodium silicate, resin, etc.

1. Green Sand Mold

Green sand mold is the most commonly used type of sand mold in sand casting.

It uses clay as a binder and adds a certain amount of water to the sand mold.

The advantages of green sand mold are:

-Simple to manufacture and low-cost

-Wide applicability, can be used to cast castings of various materials

-Good high-temperature resistance and corrosion resistance

The disadvantages of green sand mold are:

-The strength of the sand mold is low and it is easy to deform

-Long baking time and low production efficiency

2. Sodium Silicate Sand Mold

Sodium silicate sand mold uses sodium silicate as a binder.

The advantages of sodium silicate sand mold are:

-High sand strength, not easy to deform

-Short baking time and high production efficiency

The disadvantages of sodium silicate sand mold are:

-The Manufacturing Process is complicated and the cost is high

-Higher requirements for casting equipment

3. Resin Sand Mold

Resin sand mold uses resin as a binder.

The advantages of resin sand mold are:

-High sand strength, can be used to cast large and complex castings

-Good fluidity and air permeability

-The surface finish of the casting is high

The disadvantages of resin sand mold are:

-Resin sand pollutes the environment

Conclusion

Green sand mold, sodium silicate sand mold, and resin sand molds are the three types commonly used in sand casting.

Each type of sand mold has its advantages and disadvantages. The type of sand mold should be selected according to the specific requirements of the casting.

If you want to learn more about sand casting, please contact us!

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Choosing the Right Material for Investment Casting

What is Investment casting?Investment casting is a metalworking process that involves creating a shape, called the investment, out of wax or other materials. Th...

-

Investment Casting: Unveiling the Magic of Wax Patterns

This guide delves into the various types of investment casting waxes, their unique properties, and how they contribute to the success of this versatile techniqu...

-

Differences between Die Casting and Investment Casting

What does investment casting mean?Investment casting is also called lost wax casting or dewaxed casting. Making parts by investment casting is usually a more ti...

-

Forged vs Cast:Which Is Better

Metalworking processes play a crucial role in shaping various components and structures used in diverse industries.Among these processes, forging and casting ar...

-

The Mechanical Property Of Stainless Steel Precisoin Casting Is Higher Than That Of Cast Iron

The mechanical property of stainless steel precision casting is higher than that of cast iron, but its casting property is worse than that of cast iron. It has ...

-

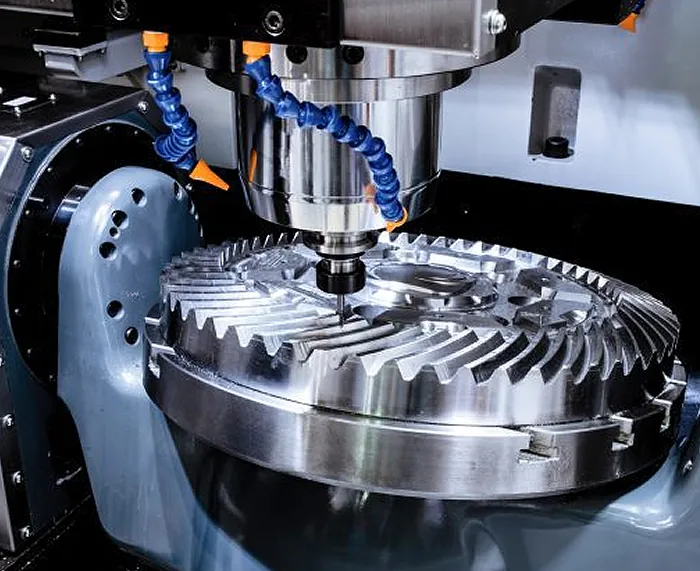

How to Maximize the Efficiency of CNC Machining

CNC machining efficiency plays a crucial role in optimizing productivity and reducing costs. Here are some effective ways to improve CNC machining efficien