Heat Treatment Trends of Heat Resistant Alloys for A-USC Power Generation

Author: SAIVS Date Published: Jan 04,2026

The development of 700℃ class Advanced Ultra Supercritical power generation technology has placed unprecedented demands on heat resistant alloys and superalloys.

These materials must operate reliably under extreme temperature, pressure, and long-term creep conditions.

As a professional supplier of high-performance alloy solutions, saivs focuses on translating advanced material research into stable, manufacturable, and commercially viable products for global energy and industrial users.

Role of Heat Treatment in A-USC Heat Resistant Alloys

Heat treatment is a core process that determines the microstructure stability and mechanical performance of heat resistant alloys.

For turbine impellers, boiler tubes, and main steam pipes, optimized solution treatment and aging processes directly influence creep strength, fatigue resistance, and crack susceptibility. Modern A-USC systems require alloys that maintain structural integrity beyond 700℃ for decades of service.

Ni-Based Superalloys for Turbine Impellers

Ni-based superalloys derived from compositions similar to Inconel 617 have become a primary research direction for turbine impellers.

By adjusting carbon, chromium, cobalt, molybdenum, aluminum, titanium, and trace elements, researchers have improved high-temperature strength and Forging performance.

Large-scale forged impeller samples demonstrate that uniform heat treatment is essential to control grain size and precipitation behavior across thick sections.

The optimization of heat treatment parameters allows forged Ni-based alloys to achieve consistent creep resistance in both hub and blade regions.

This consistency is critical for industrial users seeking long-term operational reliability and reduced maintenance costs.

Cast Heat Resistant Alloys as Alternative Solutions

Cast Ni-based alloys with stepped wall thickness designs have been evaluated as alternatives for A-USC applications.

Heat treatment plays a decisive role in reducing elemental segregation and improving creep strength uniformity.

Proper homogenization treatment minimizes the adverse effects of microsegregation that can otherwise lead to premature failure.

For manufacturers and buyers, cast alloy components with controlled heat treatment offer cost advantages while meeting performance targets for high-temperature service.

Ni-Fe Based Superalloys and Trace Element Control

Ni-Fe based superalloys are promising candidates for large turbine impellers due to their balanced cost and performance.

However, trace elements such as boron, carbon, and sulfur significantly influence creep behavior and weldability.

Heat treatment strategies must be carefully designed to stabilize carbides and suppress harmful phase formation.

Industrial-grade alloy production requires precise control of chemical composition combined with repeatable heat treatment cycles.

This ensures that large components meet both mechanical property specifications and manufacturing tolerances.

Heat Treatment of Welded Dissimilar Materials

A-USC turbine designs increasingly adopt welded structures combining Ni-based and Fe-based alloys.

The heat treatment of welded joints is critical for maintaining structural stability at high temperature.

Thermal aging studies show that improper post-weld heat treatment can lead to microstructural degradation at the interface.

Optimized heat treatment improves joint durability, making welded impeller solutions practical for high-efficiency power generation systems.

Precipitation Strengthening and Creep Resistance

Alloys such as 23Cr-45Ni-7W rely on controlled precipitation of M23C6 carbides and Laves phases to enhance creep strength.

Heat treatment governs the size, distribution, and stability of these phases.

Improper aging can accelerate coarsening and reduce long-term performance.

By contrast, solid-solution strengthened alloys with optimized heat treatment offer improved ductility and resistance to stress relaxation cracking.

These characteristics are particularly valuable for main steam pipes and boiler components operating under cyclic thermal loads.

Forged Ni-Based Alloys and Phase Stability

Forged Ni-based superalloys exhibit different precipitation behavior compared to cast alloys.

Heat treatment must account for lattice mismatch between strengthening phases and the matrix.

Morphological changes in precipitates can significantly affect creep life.

Advanced heat treatment design allows forged alloys to achieve a balance between strength and toughness.

This balance is essential for high-value components supplied to power generation, petrochemical, and energy infrastructure markets.

Industrial Value and Procurement Advantages

For global buyers, selecting heat resistant alloys is not only a material decision but also a processing decision.

Reliable heat treatment capability ensures stable quality, predictable service life, and compliance with international standards.

SAIVS supports customers with alloy solutions that integrate advanced research with industrial-scale production.

By combining optimized alloy composition, precise heat treatment, and strict Quality Control, enterprises can reduce operational risk and improve plant efficiency.

This approach delivers measurable value in long-term high-temperature applications.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

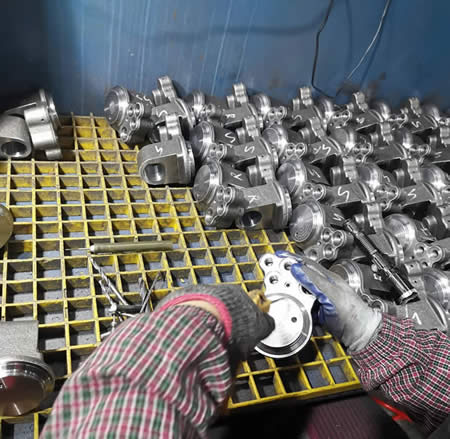

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Precision Quality Control & Mold Design for High-Performance Die-Cast Aluminum Parts

Quality Control of Raw Materials for Die-Casting Aluminum Alloy PartsRaw materials determine the baseline quality of every die-cast aluminum component prod

-

Choosing the Right Material for Investment Casting

What is Investment casting?Investment casting is a metalworking process that involves creating a shape, called the investment, out of wax or other materials. Th...

-

When to Choose Die Casting and When to Select for Injection Molding

Die casting vs Injection Molding: A detailed guide comparing these manufacturing processes for metal & plastic parts.

-

How Metal Oxide Films Affect the Quality of Aluminum Alloy Castings

Aluminum alloy casting is a critical process in modern manufacturing, widely used in automotive, aerospace, construction, and industrial machinery. However

-

Ten methods for deburring in pressure casting

During the production process of pressure casting, burr is unavoidable due to pressure impact and insufficient locking force. In recent years, with the increasi...

-

Aluminum: A Versatile Metal with a Duality in Spelling

Aluminum is a versatile metal with a wide range of applications. This article will discuss the history of aluminum, its properties, and its applications.